1. INTRODUCTION

In the demand to decrease global warming and minimize the environmental impact caused by waste and disposal methods such as wood ash, the following are some of the most important factors to be taken into consideration (Kumar et al., 2022). Waste disposal contributes to greenhouse gas emissions reduction (Arunkumar et al., 2022b). Meanwhile, the combustion of wood used in cottage industries that is currently used, is the effect of large masses accumulated worldwide, renewable energies seek to minimize dependence on fossil fuels such as biomass with wood resulting in large amounts of waste with polluting consequences that affect the environment (Gabrijel et al., 2021; Šantek et al., 2021). However, the possibility of using fly ash from the combustion of woody biomass - girasol as an admixture in concrete arises from the need to improve the mechanical properties as such (Jura & Ulewicz, 2021).

Therefore, the recycling of waste instead of traditional materials has become an increasingly relevant and recurrent topic of growing interest among researchers (Choudhary et al., 2021). This shows the potential of waste used as construction material in the development of pavements in developing countries such as India, where consumption is higher and availability of disposal space is lower (Vishnu & Singh, 2021). Thus, scientific studies confirm that the beneficial use of wood ash in concrete to replace Portland cement showed the greatest potential environmental benefits (Gaudreault et al., 2020). For this reason, it is an alternative as a cementitious material (Chowdhury et al. 2014). Likewise, alternative concrete based on wood ash saves almost 24,5% of CO2 and fly ash saves more than 28,5% compared to normal concrete (Shaker et al. 2020).

The use of Copaiba wood is a very popular material in the handmade brick industry, and several publications have been published on the reuse of this material in the structural concrete mix. The results of these studies have allowed obtaining optimal benefits in concrete, as in the case of wood ash, studies mention that agricultural ashes contain a high silica content of more than 50%, since the addition of ashes from agricultural waste reduces concrete slump, except for concretes mixed with ashes from palm oil fuels, wheat straw ashes and rice straw ashes (Charita et al., 2021).

Regarding the fresh properties of concrete, authors such as Rahul-Rollakanti et al. (2020) mentioned that it is recognized that the workability of the concrete was diminished by the addition of the alternative materials. This contributes due to the capacity of biomass ash to retain part of the absorbed water up to values of 40% during 24 hours, as mentioned by the researchers Rodríguez-Álvaro et al. (2022).

Other studies regarding its workability indicated that there were no significant differences in the control mix and the mixes developed incorporating waste paper ash and wood ash, however the results that, when adding between 25-50% of waste paper ash or 25% of wood ash, the mechanical properties (compressive strength, flexural strength) of the control mixes decreased slightly, with the possibility of partially replacing fly ash by up to 50% of wood ash or 25% in the preparation of the concrete according to Owaid et al. (2021). But according to what Kannan & Raja (2021) observed, the maximum compressive strength achieved was 83 N/mm2 in concrete mixed 10% wood ash + 20% metakaolin for high strength concretes. Other studies such as, Kanmani et al. (2021) where they refer that steel fiber reinforced concrete in which cement was partially replaced with wood ash between 0 to 20% with 5% increments, it was observed that for 10% wood ash considerable benefits in compressive strength and flexural strength were achieved. On the other hand, according to Vijay et al. (2021), when wood ash was added to concrete at 10%, 15%, and 20% by weight of cement, they observed a maximum improvement of 8,24% in compressive strength at 28 days of curing by using 15% wood ash, being feasible and sustainable to develop concrete up to 15% as a partial substitute material for cement. Nevertheless, the studies conducted by Caldas et al. (2021) observed that the compressive strength test as a functional unit in the mixture containing 40% metakaolin and 10% wood ash reached values of 9,27 MPa with respect to the reference sample of 6,65 MPa, which allowed concluding that the substitution of Portland cement by both materials is a promising strategy.

For the development of pavement concretes, rice husk ash waste and wood sawdust is used as a replacement for sand to develop low-dose concretes, with good results in environmentally friendly rigid pavement structures in the future (Alhazmi et al., 2021). Considering the studies of Fořt et al. (2020) mentioned that concrete mortars with biomass fly ash reveal preservation of compressive and flexural strength up to 30% by weight of cement replacement, on the contrary, higher doses of ash induce a gradual decrease of mechanical performance. In addition, the impact of wood ash stands out with very good results in the workability of the concrete mixture, in the resistance to compression and bending in its hardened state, in the absorption of water, in the shrinkage due to drying, in the carbonation and chloride permeability of concrete (Danraka et al., 2019).

Based on the information mentioned above and as recommended by Da Costa et al. (2022), sustainable alternatives should be sought that achieve a better recovery of wood ashes for the incorporation in concrete mixtures, including in the preparation of mortars and soil stabilization; as well as the potential it has in controlling the deterioration induced by the alkali-silica reaction in the concrete mix (De Souza et al., 2022).

To the best of our knowledge, Copaiba wood ash has not been applied before in the concrete under study, only with another variety of wood. In this context, the objective of this work was to study the influence generated by the addition of residual wood ash on the physical-mechanical properties of structural concrete, in percentages of 0%, 8%, 12% and 16% by weight of cement. This study promotes the use of waste wood ash produced by artisanal brick kilns in the proposed area in the city of Chiclayo, Peru. The use of residual wood ash acquired from artisanal brick kilns can be considered sustainable and viable. Therefore, by reducing the discarded raw material it has a positive effect on reducing environmental pollution, and preventing this waste product from ending up in landfills or dumps near the city. Likewise, it contributes to the feasibility of the use of this type of residual ashes in the physical-mechanical behavior of structural concrete, from a waste material from artisanal brick kilns in the production of concrete

2. MATERIALS AND METHODS

2.1. Materials

2.1.1 Aggregates

The stone aggregates were supplied from the Pacherrez quarry, where the coarse aggregate was extracted, and the La Victoria quarry, where the fine aggregate was extracted, located in the department of Lambayeque, Peru. Considering a fineness modulus of 2,58 and a nominal maximum size of 12,70 mm. The main physical and mechanical properties of the fine and coarse aggregates are summarized in Table 1.

2.1.2 Ordinary Portland cement

The cement for this research work was Portland cement Type I of 42,5 kg, which complies with the ASTM C150 standard for the classification, manufacture, distribution and use of cement, with a specific weight of 3,15 gr/cm3, respectively according to the parameters of the ASTM C188 standard, and the specifications are shown in Table 2.

2.1.3 Wood ash

The wood ash (WA) was collected from artisanal brick kilns, at a temperature of approximately 800°C during two days of the kilning process, with Copaiba wood as fuel. The ash extracted is shown in Figure 1.

Additionally, WA from brick kilns in the area was obtained, obtaining a specific weight of 0,70 gr/cm3 which passed the N°200 mesh and its absorption capacity of 4,23%. The chemical properties of wood ash are shown in Table 3, respectively.

2.1.4 Water

The potable water used in the investigation was clean water intended for consumption, as specified in ASTM C1602, used to prepare concrete and to immerse the concrete specimens in the curing process, respectively.

They were demolded after 24 hours of processing and finally cured by complete immersion under supervised and controlled conditions in accordance with ASTM C192M, to be subsequently tested.

2.2. Mixture design

A concrete reference design (CP) was prepared with 3 experimental mixes, the design has a target strength of f'c: 280 kg/cm2 and was prepared under the methodology of ACI 211,1, Table 4 shows the mix design for each mix. The amount of cement type I, river sand, coarse aggregate and water for all designs. Then the incorporation of each percentage of wood ash 0%, 8%, 12%, 16% with respect to the weight of cement was performed and is labeled as CP, CP+8WA, CP+12WA, CP+16WA, in order to determine the mechanical properties under the normative parameters. After performing the particle size tests, and determining the properties of the materials, a water/cement (w/c) ratio of 0,45 was used and no superplasticizer admixture was used. The experimental concrete production of cylindrical specimens and prismatic beams was carried out manually and cured in pools of water after 24 hours of setting. The prepared concrete samples had a total of 36 cylindrical molds of 150 mm in diameter and 300 mm in height for the axial compressive strength test for 7, 14 and 28 days, and the flexural strength had a total of 12 prismatic beams with dimensions of 150 mm x 150 mm x 450 mm for 28 days of rupture, as shown in Figure 2, the amounts per m3 are detailed in Table 4.

2.3 Tests to determine the physical and mechanical properties of concrete

Tests performed on both fresh and hardened concrete are vital to know the characteristics of the concrete. The tests used for the fresh state are slump, temperature and unit weight, with reference to ASTM C143M, ASTM C1064M and ASTM C138M, respectively. Likewise, for the hardened state, the axial compressive strength and flexural strength tests were performed in accordance with ASTM C39M and ASTM C78.

2.3.1 Workability, temperature and unit weight

The test to measure the workability by Abrams cone was determined according to ASTM C143M, in order to see the consistency of the mix for the structural element to be designed, as shown in Figure 3. The process of measuring the temperature of the freshly mixed concrete, according to ASTM C1064M. The unit weight of concrete is between 2200 and 2400 kg/m3 according to Shabbar et al. (2017).

2.3.2 Compressive and flexural strength

The compressive strength mentions for Xianggang et al. (2018) is the stress generated as a result of the pressure load per surface area, as shown in Figure 4. The bending test was performed in a hydraulic press loading in the middle thirds of a simply supported beam in accordance with Kett (2009), as shown in Figure 5.

3. RESULTS AND DISCUSSIONS

3.1. Fresh properties of concrete

The workability of the concrete mixtures was characterized by a reduction in slump as WA was added. Likewise, the Table 5 shows the slump test, which was carried out to indicate the influence of the addition of WA in doses of 8%, 12% and 16% with respect to the weight of the cement.

The results of the properties of the concrete in its fresh state are shown in Table 5, it is observed that the slump test, as the percentages of wood ash are added in higher percentages, reduces the workability, this may be due to the absorption capacity of this material and the additional volume it occupies, therefore, it reduces the workability. This test was carried out under ASTM C143; therefore, it was observed that as the ash doses increased, the slump decreased proportionally with respect to that indicated in said standard. The use of 8% WA reduced the slump by 12,55%, for 12% WA it decreased by 30% and for 16% WA it decreased by 40%, so that according to these obtained values it was considered that the concrete mix was not very feasible from the doses of 12 and 16% of wood ash, since it was designed for a good workability within 3" to 4", respectively. In this sense, Hamid & Rafiq (2020) and Moretto (2020) state that WA substitution between percentages higher than 10% present low workability, which causes a decrease in slump and mechanical strength, being this consistent according to the findings obtained in the present research, the 8% of WA incorporated in the mixture was optimal.

This effect can be contrasted with the findings of Rahul-Rollakanti et al. (2020) where they mentioned that the workability of concrete was recognized to be decreased by the addition of the alternative materials. This contributes due to the ability of biomass ash to retain part of the absorbed water up to values of 40% for 24 hours, which leads to a direct relationship with the required workability and strength of the concrete mix as mentioned by the researchers Rodriguez-Alvaro et al. (2022).

In addition, the results of the temperature of the fresh concrete showed a non-significant increase of a maximum of 3,5°C for the CP+16WA sample, which is considered a moderate temperature. On the other hand, the unit weight test was observed to be a relatively lower value than the standard sample when the different percentages of wood ash were added, only the CP+12%WA sample had a slight increase but not higher than the standard sample, then its value declined with the last dose of ash, This may be due to the appearance of air bubbles in the surface layer of the experimental specimens as a result of some chemical reaction upon contact with the cement and wood ash components that cause an increase in internal porosity, since it is also known that the specific gravity of the ash is lower than that of the Portland cement type I used. According to this Schmidt et al. (2020) mentioned that, on average, no specimen reached the expected density; the difference corresponds to the effect of the air trapped in the mixture, which varied between 0,77% and 2,36% of the volume.

3.2. Compressive strength

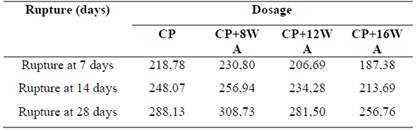

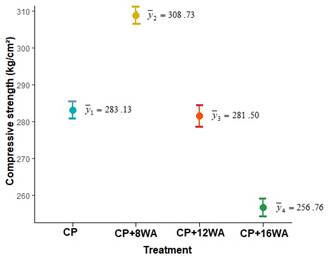

The results shown in Table 6 show that the axial compressive strength with 12% and 16% de WA had a lower performance than the standard sample at 7 days of the curing process; and a better performance was obtained with 8% de WA with 5,49% with respect to the standard. At 14 days with 8% de WA there was an increase of 3,58%, with 12% there was a reduction of 5,56% below the standard, and with 16%de WA there was the least reduction in capacity with 13,86% with respect to the standard. At 28 days, with 8% de WA there was an increase of 9,04%, with 12% there was a reduction of 0,58% below the standard, and with 16% de WA there was a reduction in capacity of 9,31% with respect to the standard. Figure 6 shows the values at 28 days according to Stripcharts of the study.

Figure 6 Study Stripcharts: Strength of concrete using partial addition of residual wood ash with respect to cement, according to compressive strength

In comparison with the research according to Elahi et al. (2015), they observed that when they incorporated doses of 10%, 15% and 20% WA, what resulted was to obtain acceptable axial compressive strength with the minimum dose of 10%, as the lower doses had better characteristics in terms of mechanical properties, unlike the current study that obtained its best characteristics in terms of compressive strength by including 8% WA, respectively.

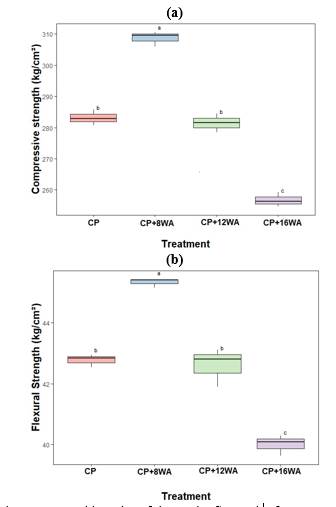

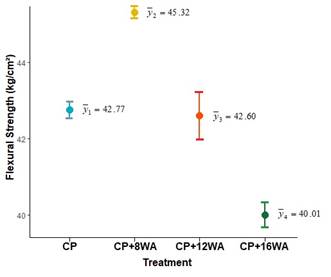

3.3. Flexural strength

As shown in Figure 7, the results of the flexural strength tests conducted under ASTM C78 parameters showed a maximum increase of 5,96% with respect to the standard specimen, using 8%WA. On the contrary, with the experimental specimens of 12% de WA and 16% de WA, there was a significant reduction of 0,38% and 6,45% with respect to the standard specimen, results at 28 days of rupture, respectively. This reduction in strength may be due to the additional increase in weight of wood ash in relation to the weight of cement, which results in a weakening of the internal bond between aggregate, ash and cementitious paste, being more prone to failure, and only being optimal with the lowest addition dose.

Figure 7 Study Stripcharts: Strength of concrete using partial addition of residual wood ash with respect to cement, according to flexural strength

Meanwhile, the research of Dharmaraj & SivaKumar (2020) mentioned that replacing by cement at 5, 10, 15, 20, 25 and 30% by wood ash had optimum strength values between 25% and 30%. Likewise, according to the research conducted by Arunkumar et al. (2022a), the results of their study showed that replacing 30% of wood ash with fly ash resulted in better performance in all mechanical parameters of concrete, since from 40% to 100% substitution its strength progressively decreased below half of its standard strength at 28 days of rupture. However, the findings of Shaker et al. (2020) support that wood ash can be used up to 25% in total weight of cement, the concrete does not lose its considerable strength in 28-day tests, as doses higher than 25% or even 50% reduced the strength to half of the 0% replacement in 28-day tests

According to Bikoko (2021), he used eucalyptus wood ashes where they mention that they have a negative influence on the strength of concrete when replaced and added with respect to the weight of cement, respectively. Finally, according to the findings of Zhuge et al. (2021) the mechanical properties of concrete deteriorate with high wood ash content, with the appropriate and recommended addition being less than 10% of cement replacement.

3.4. Statistical analysis

Based on Figure 8(a), regarding the compressive strength variable, the one-factor analysis of variance test, reached a p-value of significance less than 0,05 (p=7,17e-08<0,05), so we can confirm that there is a significant difference in the average compressive strength between at least two treatments, as well as the Tukey's multiple comparisons test, which allowed us to identify the CP+8WA treatment as significantly different from the other treatments, as well as the treatment that maximized the compressive strength, with an average sample strength of 308,73 kg/cm². As shown in Figure 8(b), corresponding to the flexural strength variable, the p-significance of the single-factor analysis of variance test, presented a value less than 0,05 (p= 1,21e-06<0,05), generating the rejection of the equality of means, in addition, the Tukey post hoc test for multiple comparisons showed that the CP+8WA treatment presented a significant difference with the other treatments; likewise, it was the treatment that managed to maximize the flexural strength variable, whose sample average recorded was 45,32 kg/cm².

4. CONCLUSIONS

This study is based on the development of a concrete with wood ash obtained from artisanal brick kilns in the area of the city of Chiclayo, Peru, and on the analysis of its physical and mechanical properties. The objective of the study was to evaluate the influence of wood ash as an addition as a function of cement weight on the physical and mechanical properties of structural concrete. The results allowed the following conclusions to be drawn:

With respect to the slump test the addition of wood ash reduced as more volume of wood ash was added, reducing between 12,50%, 30% and 40%. In addition, the unit weight test had the tendency to reduce its value the higher the percentage of wood ash, respectively.

The temperature of the concrete in its fresh state had a tendency to increase its internal heat up to 3,5°C, respectively the higher the amount of ash incorporation.

The compressive strength was influenced with the addition of WA in doses of 8%, 12% and 16% had a percentage increase of 9,04%, and a reduction of its strength of 0,58% and 9,31%, respectively, with respect to the standard sample, showing strengths below the standard sample.

The flexural strength test was influenced by the addition of WA at doses of 8%, 12% and 16% with a percentage increase of 5,96%, and a reduction in strength of 0,38% and 6,45% below the standard sample.

In general, it was concluded that the present study proved that it is feasible to use wood ash from Copaiba trees in the preparation of concrete, being acceptable for concrete slabs, rigid pavements, slabs, beams and columns. However, the percentage higher than 12% of wood ash influenced the reduction of its properties, being 8% of wood ash a suitable percentage in the improvement of the mechanical properties of concrete being a sustainable solution reducing the storage of areas where this waste material is dumped, offering a better quality of life to the rural population and a sustainable construction environment. However, the use of WA is recommended and further research on this waste by-product of the WA clay brick industry is recommended.