1. INTRODUCTION

Plastic pollution has drawn considerable environmental problems during the last centuries. It is estimated that over 50 million tons of plastic waste are globally produced each year (Thilagavathi et al.,2018 . The low degradation and biodegradation rates of these discarded plastics hinder solid waste management and increase plastic debris in landfills, incineration as well as the propensity for dispersion in the environment (Ahmed et al., 2018; Gu, 2017). Therefore, plastic pollution affects not only terrestrial and aquatic ecosystems but also causes negative consequences on flora and fauna (UNEP, 2018; Webb et al., 2013).

Over the past decades, there has been a keen interest to find eco-friendly materials namely, bio-based and biodegradable polymers to replace traditional plastic (Avérous & Pollet, 2012; Sabbah & Porta, 2017). In the vast group of innovative alternatives obtained from renewable resources, polyhydroxyalkanoates (PHAs) and polylactic acid (PLA) are recognized by their important potential for industrial production (Niaounakis, 2014).

PLA, a chemically synthesized biopolyester, is commercially used in several applications due to its good processability, transparency and feasibility to be degraded in soil or compost in shorter time than conventional plastics (Pantani & Sorrentino, 2013). However, some drawbacks like fragility, relative high water and gas permeability, and so forth limit its use in some applications (Xiao et al., 2012; Zeng et al., 2015).

PLA can degrade and convert to water, carbon dioxide (CO2), methane (CH4) and other small molecules under several conditions; but, the biodegradation rate of PLA is relatively slow compared with conventional polymers (Yang, et al., 2015). The biodegradation process of PLA could be affected by morphology, purity, chemical structure, shape, as well as its molecular weight and the presence of additives (Lv et al., 2017; Sharma et al., 2021). It has been reported that higher molecular weight PLA exhibited slower degradation kinetics as compared to the lower molecular weight one. In addition, the L enantiomer presence promotes biodegradation. High grade of crystallinity reduces the biodegradation rate. After biodegradation process, crystallinity of material increases and molecular weight decreases (Pujari, 2021; Brdlík et al., 2021).

On the other hand, starch is a widely available and inexpensive natural biopolymer. For further processing as a thermoplastic material, the addition of plasticizers such as glycerol (Altayan et al., 2017, 2021), sorbitol (Nevoralová et al., 2019; Smits et al., 2003) glycols (Correa et al., 2017; Nevoralová et al., 2019), maltodextrins (Xiaofei et al., 2004) or urea (de M. Teixeira et al., 2012; Kaseem et al., 2013) is required. Even though there is a great number of investigations focused on corn and wheat thermoplastic starches (Altayan et al., 2021), there is no comprehensive studies based on Andean region species, such as achira (Canna edulis), jícama (Smallanthus sonchifolius), mashua (Tropaeolum tuberosum), mauca (Mirabilis expansa) and oca (Oxalis tuberosa) (Espín et al., 2004).

Blending PLA with a natural biopolymer, e.g. starch, could not only accelerate the biodegradation rate of the final material but also increase the application range in products with short life cycles (Akrami et al., 2016). Nevertheless, these blends usually show poor mechanical properties due to the incompatibility produced by the hydrophobicity of PLA and hydrophilicity of starch (Xiao et al., 2012). Because of this fact, physic defects like holes and cavities are usually generated in the interface PLA-starch (Orozco et al., 2009).

To overcome incompatibility drawbacks, compatibilizers that improve miscibility, processing and flexibility are added into the blend (Shirai et al., 2016). Maleic anhydride, acrylic acid and diphenylmethane diisocyanate are some of most common compatibilizer agents tested (Xiong, Yang, et al., 2013). Nevertheless, the toxicity of these compounds limits their usefulness, since they are poisonous and consequently dangerous for health (Wang et al., 2008). In this context, polyvinyl alcohol (PVA) could increase the compatibility in PLA - starch blends (Lu et al., 2009) in view of emulsifying and adhesive properties, affordable cost and a low biodegradation rate (Wittaya, 2012). Therefore, the aim of this study is to look at the mechanical, thermal, infrared and biodegradability characteristics of PLA - achira starch blends compatibilized by PVA.

2. MATERIALS AND METHODS

Materials

PLA was obtained from NatureWorks Co. (USA). Density of PLA was 1.24 g/cm3. Food grade achira starch (23.8 % amylose) was purchased from Colinas Verdes Foundation (Ecuador). Glycerol laboratory grade was supplied by Toptrading Productos Químicos (Ecuador) and 88 % hydrolysed PVA was obtained from Sekisui Chemical Co., Ltd. (Japan).

Methods

2.2.1 Preparation of PLA-starch blends

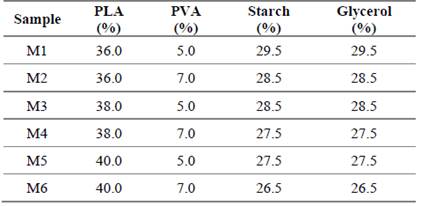

Achira starch was sieved through a mesh No. 200 (HUMBOLDT, model H-3920) and dried at 40 °C for 2 h in oven (MM Group VENTICELL, model LSIS-B2V/VC 55). In addition, PLA and PVA were dried at 40 °C for 48 h. Conditioned raw materials (starch, PLA and PVA) and glycerol were manually pre-mixed at room conditions, and then fed into a mixer (HAAKE, model 557-9300) at 120 °C for 20 min with a rotation speed of 90 rpm. Afterward, films of 0.96 ± 0.03 mm thick were obtained using a heated lab press (CARVER, model 2112) at 120 °C and 17 MPa for 10 min. The component ratios were determined according to a previous work (Silva et al., 2018). The final composition of each formulation is presented in Table 1.

2.2.2. Mechanical characterization

Tensile characteristics in terms of tensile strength, elongation at break and Young´s modulus were assessed at room temperature (18 °C) on a universal testing machine (Instron, model 3365) according to the standard ASTM D882-18 with a crosshead speed of 12.5 mm/min. A total of five specimens was tested for each sample formulation.

After tensile test, the fractured surfaces of each specimen were analyzed through scanning electron microscope (TESCAN, model VEGA II LMU) with a voltage acceleration at 15 kV. All samples were kept under liquid nitrogen and the fractured surfaces were coated with gold particles before observation.

2.2.3. Thermal analysis

Differential scanning calorimetry (DSC) analysis was performed using a calorimeter (Netzsch, model 204 F1). Samples were heated from -20 to 350 °C with a heating rate of 20 °C/min in nitrogen atmosphere (20 mL/min). Netzsch Proteus software was used to determine glass transition temperature (Tg), onset temperature (Tm) and fusion enthalpy of endothermic processes (ΔH). Three samples were tested for each formulation.

2.2.4. Fourier transform infrared (FTIR) spectroscopy

Attenuated total reflection Fourier transform infrared (ATR-FTIR) spectroscopy was used to obtain qualitative information about functional groups of PLA - achira starch blends. Tests were recorded on a spectrometer (Perkin Elmer, model Spectrum One). Data were collected over 16 scans with a resolution of 4 cm-1 in a range of 4000 to 650 cm-1.

2.2.5. Biodegradability of blends

It was determined using natural soil, vermicomposting method, aerobic and anaerobic conditions according to the methodology reported in literature (Funabashi et al., 2007; Iwańczuk et al., 2015; Rudnik & Briassoulis, 2011; Ruiz et al., 2013). Films were cut into 30 x 30 mm specimens for testing. The extent of biodegradation was estimated from the weight loss Wloss (%) of all samples based on equation (1):

where Wo and Wf are the weights of specimen before and after to be buried in aerobic conditions, natural and vermicompost soil for 60 days. For anaerobic tests, the biodegradation was determined from the measurement of daily CH4 production for 10 days. The samples were tested twice.

Natural soil tests: Experiments were carried out in a glass bin of 100 x 30 x 40 cm at 18 °C. Specimens were buried in 2 cm deep in soil to simulate the environmental conditions. The moisture content and pH were around 8% and 7.5, respectively.

Vermicomposting technique: Samples, soil and worms (Eisenia foetida) were placed in 0.5 L glass reactors (sample/worm ratio 4:1). All test flasks were incubated (Mermet IF55 Plus series) at 60 °C. The moisture content was about 25% at pH 7.5.

Aerobic conditions: These experiments were conducted at 18 °C in 2 L laboratory containers. Samples were buried under 5 cm of soil which was collected on top of a landfill of eight-month period of maturation in a weight ratio of 1:10. The soil was manually stirred to maintain a constant mixture. The moisture content was 32% at pH 8.

Anaerobic conditions: Tests were performed in 2 L bottles with hermetic seals placed in a carbon dioxide (CO2) incubator (Blinder CB53-UL) at 60 °C. Samples and soil weight ratio was 1:10. The specimens were buried under 5 cm of soil that was obtained from one meter below a landfill surface of eight-month period of maturation. The produced biogas (CO2 and CH4) was passed through a 0.5 M sodium hydroxide solution to absorb CO2. The amount of CH4 was obtained by the water displacement method. The moisture content and pH were adjusted to 35% and 8, respectively.

3. RESULTS AND DISCUSSION

Tensile evaluation

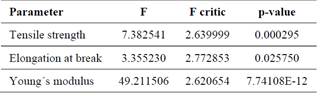

The tensile results and their analysis of variance (ANOVA) are presented in Figure 1 and Table 2, respectively. Since p-value < 0.05, there are statistical differences in tensile strength, elongation at break and Young´s modulus. It is noticed that, the higher concentration of compatibilizer increased tensile strength, which was in good agreement with other studies (Ke & Sun, 2003; Lu et al., 2009). Due to the amphiphilic behavior of PVA, it could act as a ¨physical bridge¨ between starch and PLA (Koh et al., 2018). From this perspective, the interfacial affinity between PLA and starch would be improved. Moreover, a large amount of PVA slightly increased the elongation at break due to the enhancement of the interaction between PLA and starch. However, this effect is limited to low PVA content; higher percentages of PVA have not modified elongation of PLA-starch blends (Ke & Sun, 2003).

Additionally, PVA and glycerol influenced Young´s modulus due to flexibility and compatibility of those substances with starch. The reduction of elastic modulus when the compatibilizer increased was also found in other investigations (Akrami et al., 2016; Shirai et al., 2016). Park et al. (2000) reported that Young´s modulus of PLA decreased at least 60 % when 10 % starch was incorporated. In the present research, as PVA and PLA content increased, starch and glycerol fraction decreased. Therefore, this reduction could also affect Young´s modulus results.

On the other hand, the high tensile strength of PLA (110.32 MPa) changed the tensile strength of samples. This effect was attributed to the rule of mixtures which assures that blend properties are proportional to the component ratio (Akrami et al., 2016). Nevertheless, results evidenced a negative deviation behavior of rule of mixture. Similar observations were also reported by Esmaeili et al. (2019), who associated this fact to plasticization of PLA with glycerol. This polyol caused an increment in the chain mobility and blends became more flexible and ductile (Lu et al., 2009). The variability in tensile strength and Young´s modulus suggested internal defects in samples due to the presence of local stress concentrators (Alcalá et al., 2002). The inequitable distribution of tensions, i.e., applied load, caused complex deformation and rupture mechanisms (Arana & González, 2002).

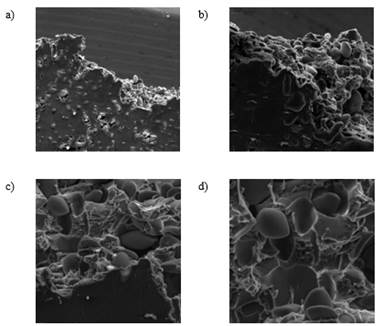

Figure 2 shows SEM images of the fracture surface of M6 sample. It is worth noting that, all samples presented similar fracture surface. From the images, rugged surfaces as well as the presence of starch granules are noticeable. The observed granules were associated to densely-packed semicrystalline structures with non-polar characteristics. These granules could affect interaction PLA-starch (Orozco et al., 2009; Shirai et al., 2016; Soares et al., 2013; Ning et al., 2010).

Thermal analysis

DSC data and their ANOVA are shown in Table 3 and Table 4, respectively. It is observed statistical differences in thermal properties due to p-value < 0.05. Particularly, each sample presented a single Tg between the Tg of pristine components, with 64.9 and 70.9 °C for PLA and PVA, respectively. These values are in agreement with those reported in literature (Aydin & Ilberg, 2016; Xiong et al., 2013). According to Rozsa et al. (2004), the presence of a single Tg value evidences an interaction between the components in the blend (Rozsa et al., 2004).

Even though there was a slight Tg variation in each sample, around 0.9 ºC, these values increased proportionally to PLA and PVA contents. Colonna and Buleon (2010) report that Tg values increase directly with crystallinity amount present in the blend, due to restriction of polymer chains mobility (Colonna & Buleon, 2010). In this context, PLA and PVA contributed to the slight increase in Tg values. Besides this, as PLA and PVA contents increase in each sample, the proportion of glycerol decreases. Aydin and Ilberg (2016) consider that plasticizers, which are low molecular weight components, reduce Tg values (Aydin & Ilberg, 2016); consequently, the addition of glycerol in higher proportions in the samples produces Tg reduction in the blends. According to Chotiprayon et al. (2020), this behavior could be the result of the glycerol migration from the thermoplastic phase which allows mobility of PLA chains. Da Róz et al. (2006) reported that melting transition appears frequently as a large multiple band, which values are shown in Table 3.

Table 3 DSC results for the thermal transitions of PLA - achira starch blends and pristine materials.

Regarding thermal transition behavior, the results presented Tm closed to the PLA crystallinity melting point, around 150 °C (Martin & Avérous, 2001). The endothermic process continues with the PVA melting (Aydin & Ilberg, 2016) and mainly to the phase change of glycerol at 290 °C (Benjumea et al., 2009; Müller et al., 2016). Colonna and Buleon (2010) state that the addition of a plasticizer reduces the melting point due to it improves the mobility of the polymer chains (Colonna & Buleon, 2010); thus, it is evident that Tm decreased with greater proportions of glycerol in the samples. Additionally, ΔH values were incremented moderately with increasing plasticizer content. This behavior was in concordance with the study proposed by Da Róz, et al. (2006).

FTIR evaluation

Figure 3a shows spectra of PLA, PVA, starch and glycerol. Characteristic absorption bands of PLA were associated to -CH stretching vibration (2956 cm-1), stretching vibration of -C=O group (1757 cm-1) and bands corresponding to -C-O stretching vibration of ester bonds (1076-1150 cm-1) (Orozco et al., 2009). The PVA spectrum shows -OH (3265 cm-1), -CH (2934 cm-1), -C=O (1732 cm-1) and -C-O-C (1105 cm-1) groups (Mansur et al., 2008). Furthermore, infrared results of starch evidenced characteristic bands of -OH (3433 cm-1), stretching vibration of -CH (2851-2920 cm-1), deformation of the OH groups from the bound water (1645 cm-1) and C-O stretching (997-1190 cm-1) (Andrade et al., 2012). Absorption bands of -OH stretching (3294 cm-1), -CH stretching (2880-2936 cm-1), -CH bending (1480-1190 cm-1) and -C-O- stretching (1110-990 cm-1) were observed in glycerol spectrum (Ahmed et al., 2010).

As can be seen in Figure 3b, all PLA - starch blends spectra show similar absorption bands. However, the -C=O had shifted to a lower wavenumber (1747 cm-1) compared to PLA and to a higher region contrasted to carbonyl group of PVA. Moreover, the -C-O stretching shifted to a low wavenumber (1022 cm-1) compared with absorption bands of PLA.

In addition, the -OH in PVA is shifted to higher wavenumber in PLA - starch blends (3271 cm-1) and the -OH bands width of starch and PVA are reduced. These changes are observed in Figure 3a. Furthermore, the -OH group in glycerol was moved to a lower wavenumber, which was probably produced by the weakening of intramolecular and intermolecular hydrogen bonds between starch molecules because the presence of glycerol and its plasticizing effect. These variations demonstrate the formation of new hydrogen bonds between starch and PVA (Chen et al., 2008; Popescu et al., 2018). On the whole, FTIR study suggested that the mentioned groups were involved in the interaction between components which was associated to a possible hydrogen bonding between the -C=O from PLA and the -OH of starch (Ke & Sun, 2003; Yew et al., 2005).

Biodegradability of blends

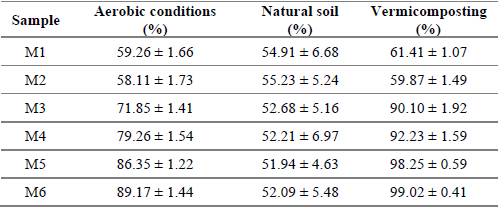

The results of degradation tests, in terms of mass loss percentage, are presented in Table 5. Overall, there was a notorious variation of biodegradability in aerobic and vermicomposting tests, whereas natural soil evaluation showed a minimum change in percentage of biodegradability. Considering this fact, M5 and M6 samples exhibited higher biodegradation values, aerobic and vermicomposting results showed an important influence of PLA content on the degradation level. Thus, there was not possibly significant incidence of PVA composition on blends biodegradation. In the case of natural soil, all the samples achieved similar results; however, the dispersion observed in this test did not enable a specific tendency to be determined. The minimum change indicated a relative low degradation rate of the studied blends in natural soil when compared with the other tests. Consequently, these results may be associated with the slow hydrolysis process at the test temperature and to the heterogeneous distribution of microorganisms in the natural soil environment (Karamanlioglu et al., 2017).

Râpă et al. (2014) found that films with the highest percentage of starch had the highest values of weight loss. The mentioned results were established when the effect of starch content on the biodegradability starch/PVA blend films prepared using the melting technique was determined in soil during a period of 30 days, which differs from the results obtained in the present study.

Some studies indicate that starch/PVA blends are not easily biodegraded in environmental conditions. However, a certain degree of biodegradation was achieved in one study when starch/PVA films cast by the solvent method were exposed to soil containing manure. An increase in the biodegradation rate was favored by the increase of starch content. Even though, ultimate weight loss did not exceed 40% over a period of 3 months and the authors affirm that this starch/PVA blend plastic film may not degrade easily in natural conditions (Raj, 2004), these values are lower than the ones reported in this study.

Lim et al. (2021) reported that in a soil buried test, the samples with the highest concentration of starch in starch/PVA blends showed the lower degradation, concluding that this behavior could be produced by the PVA solubility in water. When water was absorbed onto the hydrophilic groups through hydrogen bonding or weak electrostatic forces, the film could easily be dissipated (Lim et al., 2021). These results are in agreement with the vermicomposting and aerobic tests values of the present study for M6 sample, in which the PVA content is the highest. Even though the PVA proportion is the highest, it is quite low when compared to the PLA and starch proportion in blends M5 and M6. In this context, some authors indicate that the presence of starch is the main factor in the degradation of PLA/starch blends, since starch granules hydrolyze and affect the mechanical properties of PLA, being this effect being more evident when the starch content is higher (Lv et al., 2018; Wilfred et al., 2018).

Both aerobic and vermicomposting tests presented a level of degradation greater than 60%, which shows the ability of the material to biodegrade in short periods under the conditions of this investigation (Shi et al., 2011). These high values may be caused due to PLA and PVA’s susceptibility to be hydrolyzed. Likewise, starch promoted not only microorganism growth but also the diffusion of water into the blend (Lv et al., 2017). Obtained results show a significant degradation under mesophilic conditions. Therefore, temperature probably had an important influence on PLA-starch blends.

As it is presented in Figure 4, the CH4 volume generated from samples are similar. This degradation behavior suggests that there was no significant influence of formulation on generated CH4 volume. During the first six days, systematic volume increase was found in all the studied materials.

It should be noted that CH4 volume change did not show a latency phase, which could indicate a very short microorganism adaptation time to the substrate. After ten days of anaerobic evaluation, samples were not visible in the soil; this behavior was probably related to the temperature of the test which favored the hydrolysis reactions of the blend components; subsequently, accelerating enzymatic reactions produced by microorganisms (Djonlagic & Nikolic, 2011; Garlotta, 2001; Hakkarainen, 2002).

Russo et al. (2009) reported anaerobic degradation of thermoplastic starch (TPS) - PVA blended films in mesophilic conditions. The blends of TPS:PVA were varied at 90:10, 75:25, 50:50, and 0:100 (w/w %). The authors concluded that a higher quantity of starch in the blend resulted in increased biogas production, and starch degraded faster than PVA, in contrast with the results of this study.

Figure 5 shows an example of the appearance of samples before and after the tests. All samples exhibited signs of biodegradation. The original shape of the film was not preserved in all cases. In aerobic conditions (Figure 5a) and natural soil (Figure 5b) white pieces were found. These were larger in the former case and smaller in the latter. Furthermore, in the vermicomposting test, the films were converted into very small pieces, with soil adhered to them.

The compostability of PLA alone compared to starch/PLA blends with different amounts of starch has also been evaluated. After 30 days, all samples tested were completely biodegraded, and no residuals were observed through visual inspection (Rudeekit et al., 2012). In addition, biodegradability of pure starch, pure PVA and a 70 % starch /PVA composite films was studied by soil burial test at ambient conditions by Patil et al. (2021). It was observed that the complete degradation of pure starch films occurred in one week, while pure PVA and 70 % starch /PVA composite film took three weeks for complete degradation. These results show a faster degradation than the one observed in this study.

3. CONCLUSIONS

PLA - achira starch blends were successfully obtained with PVA as a compatibilizer. The addition of compatibilizer agent increased both tensile strength and elongation at break, meanwhile Young´s modulus decreased. SEM micrographs of fractured surface displayed eroded and rugged surfaces with starch granules as a consequence of the uncompleted interaction between PLA and starch. On the other hand, DSC thermograms showed a single Tg value close to Tg of neat components. In addition, it was observed slight increase of Tg with PLA and PVA contents. Besides, FTIR spectra of samples suggested the formation of new hydrogen bonds between PLA and starch components, due to the shift of carbonyl and hydroxyl bands. From the biodegradability perspective, the vermicomposting method showed a great degradation level of PLA - achira starch blends caused by the microbial activity in the proposed conditions.