1. INTRODUCTION

Structures are always exposed to constant loads and deformations, as structural concrete is widely used around the world and is always prone to it. On the other hand, what is sought is a material other than cement, aggregates or additives that accompanies the concrete mix (Lee et al., 2019; Muñoz et al., 2023); in order to lighten its weight and at the same time equal or significantly improve the main mechanical properties (Chicoma et al., 2023; Xiong et al., 2019). As indicated above, there are various studies on the incorporation of materials from different origins, especially those from artificial compounds, since these can be recycled and reused (Gregorova et al., 2017); to be incorporated into the different elements that are used in the various civil works, especially for the sustainable production of concrete (De Brito & Kurda, 2020). Among these materials that can be added to the concrete mix, the Microporous Ethylene Vinyl Acetate (MEVA) stands out, since it is a residual waste input and at the same time polluting, but it can be reused and recycled (Liu et al., 2019); in this regard, recent research has shown that the MEVA has important properties that can provide favorable conditions for concrete in its hardened state (Ismail et al., 2016); especially in the significant increase in compressive and flexural strength (Ghally et al., 2022; Khan et al., 2019; Shang et al., 2023).

The MEVA is a very popular input used as footwear or insulation material, educational games, among other industries (Kulesza et al., 2020); likewise, this type of material is not biodegradable, resulting in large volumes of waste, which generates a great negative impact on the environment (Zhang et al., 2018). Among the important characteristics of this material, its density stands out, since it is very light and varies from 12.00 to 80.00 kg/m3 (Machado et al., 2019; Parra et al., 2019). In addition, it is a material that has gained great popularity in the construction industry (Marques et al., 2019), so today its use in this area is gradually increasing, especially for the production of normal and lightweight concrete (Ioana et al., 2023; Ngassam et al., 2018); including partial replacement of aggregates (Selvakumar et al., 2022); also, to establish lightweight and ultralight concrete (Serelis & Vaitkevicius, 2022; Sldozian et al., 2023); similarly, for the production of lightweight concrete blocks (Carneiro et al., 2020) and even to reduce noise, using lightweight concrete for subfloors (Pacheco et al., 2017).

On the contrary, it has been shown that the workability of concrete in the fresh state increases gradually with the use of MEVA, in relation to the doses of 5.00 %, 10.00 %, 15.00 % and 20.00 % with respect to the weight of the cement (Swarnkar & Srivastava, 2021); likewise, the settlement test shows a slight increase, as a result of the substitution of gravel in 10.00 % to 30.00 % by MEVA residues in the concrete mix, however, its unit weight is decreased as the doses of this input (Machado et al., 2019); parallel to these findings, it has been determined that the unit weight tends to be reduced by up to 22.00 % with additions of MEVA in millimeter size (Baptista et al., 2021).

Regarding the mechanical properties of concrete with MEVA inclusions, Gregorová et al. (2020) describe that the compressive strength with 75.00 % of MEVA residues did not have a significant influence, but the initial qualities of normal concrete are maintained. Despite these results Moreira et al. (2020) managed to obtain a considerable increase with 6.00 % of MEVA, in the compressive strength of up to 54.00 % and in the flexural strength it increased up to 59.00 % in relation to the standard concrete; however Khan et al. (2019) and Ahmad et al. (2022) recommend incorporations of MEVA up to a maximum of 16.00 %; although in the complementary study of Ghally et al. (2022) obtained that with 20.00 % of MEVA added to the concrete, a compressive strength of 100.00 MPa can be achieved, that is, almost double the required strength, while in the flexural strength and tensile strength obtained nearly triple the standard strength.

Almost all the findings shown in the available literature on the inclusion of MEVA in concrete generally consider a predominant size of this residue of up to 5.00 mm and the standard strength in many cases is not applicable for structural concrete. Due to this the importance arises of its study for greater ranges of strength, added to this. In Peru, there are no related studies on this material with application in concrete of structural type, since at a general level this material has been studied for lightweight concrete, for the conformation of bricks and to stabilize soils of low bearing capacity, that is why the importance of addressing their study arises.

The main objective of this research was to evaluate the influence of MEVA in the improvement of the mechanical properties of structural concrete, using for this purpose additions of MEVA in ranges of 5.00 %, 10.00 %, 15.00 % and 20.00 % with respect to the volume of concrete, to later analyze its behavior in the mixture, both in the physical properties (slump and unit weight), and in the mechanical properties (compression strength, flexural strength, tensile strength and modulus of elasticity).

2. MATERIALS AND METHODS

2.1 Materials

2.1.1 Portland cement

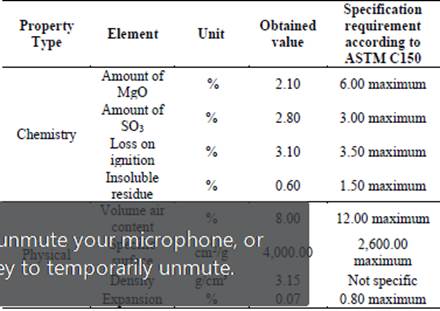

The present investigation used type I Portland cement that complied with ASTM specifications (ASTM C150, 2022). The density obtained was 3.15 gr/cm3, likewise, the chemical and physical characteristics of the cement used are shown in Table 1.

2.1.2 Aggregates

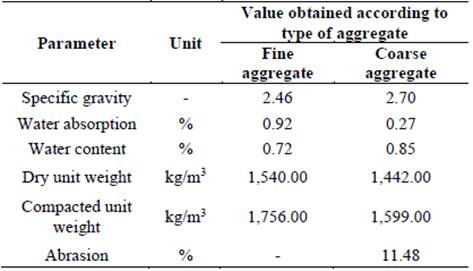

The natural aggregates were obtained from the Lambayeque Region of Peru and were characterized according to the ASTM international standard (ASTM C136, 2020). The fine aggregate was sieved showing an optimal gradation, where a fineness modulus of 3.16 was obtained, while for the coarse aggregate a nominal maximum size of 19.05 mm was determined. The complementary parameters obtained for the aggregates are shown in Table 2.

2.1.3 Microporous Ethylene Vinyl Acetate (MEVA)

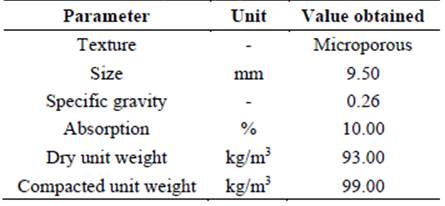

The MEVA residues were collected through a direct recycling process from some shoe insole industries in the Lambayeque Region of Peru, then the MEVA was processed in a rotary blade mill in order to obtain pieces smaller than 3/8” (9.52 mm), later it was sieved to identify its granulometric composition (Figure 1) and finally some physical properties were established through the respective laboratory tests (Table 3).

2.2 Methodology

The methodology used in this research was experimental, for which several laboratory tests were carried out in order to obtain the required strength parameters and subsequently compare all the MEVA additions in the concrete in relation to the standard strength.

In the initial stage, the natural aggregates and MEVA in its different percentages were mixed in a dry state for about 5 minutes, then cement and water were added to mix them until a combination of the materials was achieved, as the doses of MEVA increased, a segregation of the natural aggregates was observed. It did not have a special elaboration process; it is very similar to a conventional structural concrete mixing process.

Subsequently, the fresh concrete was placed in cylindrical molds with dimensions of 15 cm in diameter and 30 cm in height and prismatic molds of 15 cm in width, 15 cm in height and 55 cm in length, rodded at 25 strokes every 3 layers with a metal rod with a rounded tip. After 24 hours of pouring and setting of the concrete, the specimens were demolded to cure at room temperature by complete immersion in potable water until the day of testing at 7, 14 and 28 days. The number of specimens per test was 45 units (compressive strength), 45 units (tensile strength), 45 units (flexural strength) and 45 units (modulus of elasticity), for a total of 180 specimens. It should be noted that all these conditions and procedures were supervised in the laboratory. Figure 2 shows the hardened samples in cylindrical and prismatic form.

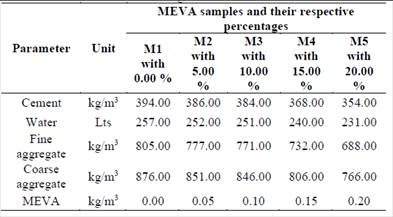

The strength was selected for a structural concrete with a control design of 21.00 MPa labeled as M1 with a water/cement (w/c) ratio of 0.65, according to the American guidelines ACI 211.1. Meanwhile, concrete samples containing MEVA at percentages of 5.00 %, 10.00 %, 15.00 %, and 20.00 % were labeled as M2, M3, M4, and M5, respectively. The final proportions are shown in Table 4, indicating in each case the respective amounts used.

3. RESULTS AND DISCUSSION

3.1 Physical properties

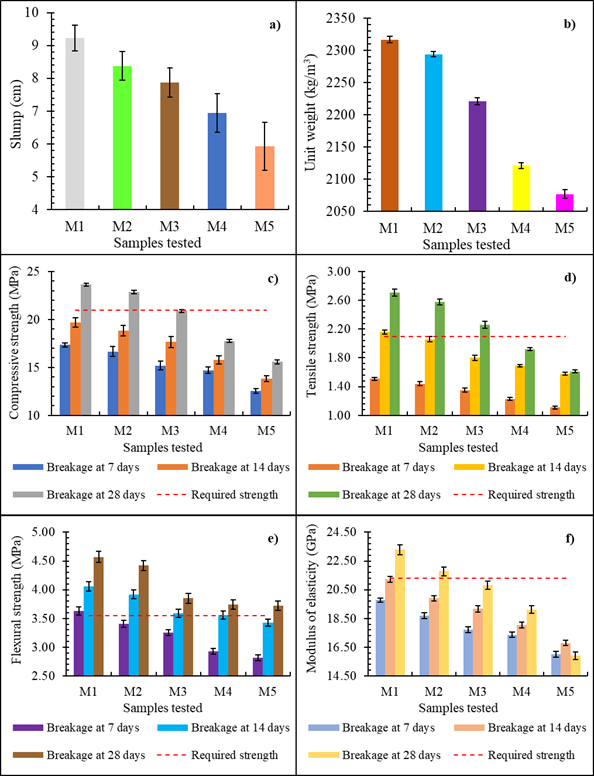

3.1.1 Slump

The slump was evaluated according to the ASTM C143 (2020) standard, finding as results a significant decrease in this parameter as the MEVA proportions increase (Figure 3a). For the standard concrete (sample M1) the range was 9.20 cm, while for the addition of 20 % of MEVA (sample M5) it reached 5.90 cm, that is, it decreased by 35.87 %. This reaction could be explained by the fact that by increasing the amount of MEVA, the water absorption also increases, finally showing a loss of workability in the concrete during the fresh state. These findings were similar to those established by Carneiro et al. (2020), Farhoud et al. (2019) and Khan et al. (2018), and since they determined similar ranges of slump reduction.

3.1.2 Unit weight

The unit weight was evaluated following the requirements of the ASTM C138 (2017) standard, subsequently the findings reached indicate that by increasing the amount of MEVA in the concrete, the unit weight can be greatly reduced (Figure 3b). As a consequence of this, the reduction varied from 0.99 % (sample M2) to 10.36 % (sample M5), in both cases with respect to the standard concrete. From what has been indicated, it can be deduced that the MEVA is displacing both the aggregate and the cement particles, whose unit weights are totally different and due to their combination in the concrete mix, this decrease occurs progressively, similar to what happened in the slump. In this context, similar studies such as the one by Dulsang et al. (2016) obtained a maximum decrease in unit weight of 66.00 % for 10.00 % addition of MEVA; on the other hand, Machado et al. (2019) managed to reduce the unit weight by 10.00 % with 30.00 % of MEVA and Farhud et al. (2019) determined maximum decreases around 36.00 % for 20.00 % of MEVA. In this sense, a maximum range of 5.00 % of MEVA is acceptable to keep the physical properties of the concrete homogeneous and therefore not directly affect the workability in the fresh state.

3.2 Mechanical properties

3.2.1 Compressive strength

The results of the compressive strength followed the provisions of the ASTM C39 (2021) standard. Subsequently, as part of the findings, a progressive decrease in this strength was obtained, especially from sample M3 to sample M5 (Figure 3c), since they did not meet the required strength at 28 days. The strength reached by the standard concrete corresponding to sample M1 with 0.00 % of MEVA reached 23.63 MPa, while sample M2 with 5.00 % of MEVA achieved a strength of 22.85 MPa, that is, it suffered a decrease of 3.30 %, but it complied with the strength compressive of design for structural concrete, as demonstrated by Farhoud et al. (2019) and Azadmanesh et al. (2021) in their respective investigations, since they indicate that up to 5.00 % incorporation of MEVA is the adequate. In this regard, for the present investigation, the value of 5.00 % of MEVA added to the concrete was optimal for the compressive strength, since said addition exceeded the strength required for structural concrete by 8.81 %.

Regarding the effect of reducing can be explained by the fact that the density of MEVA is lower than that of the aggregates, which produces a certain lightness to the concrete in its hardened state. Similar studies such as those by Dulsang et al. (2016) and Zhang et al. (2018), determined that the compressive strength for 3.00 % of MEVA was the only dose that equaled the standard strength; while Machado et al. (2019) and Marques et al. (2019) found that the MEVA values above to 10.00 % fail to match the initial standard compressive strength, so they recommend using lower doses.

3.2.2 Tensile strength

The results of the tensile strength were evaluated in relation to the ASTM C496 (2017) standard, whose findings are shown in Figure 3d. In all cases, decreases in tensile strength compared to standard concrete at 28 days were determined, where the minimum reduction was 4.80 % (sample M2) and the maximum reduction was 40.59 % (sample M5). However, when evaluated based on the minimum design tensile strength of 2.10 MPa, an increase of 22.86 % was obtained for sample M2 whose addition was 5.00 % of MEVA and an increase of 7.61 % for the M3 sample for an incorporation of 10.00 % of MEVA, for the other cases the strengths were lower.

From the foregoing, it can be deduced that the reaction produced in both tensile and compressive strength is attributed to the displacement of the granular material given by the MEVA, resulting a progressive decrease in both strengths, as well as in the density of the concrete, as the MEVA doses increase. This is demonstrated in their respective studies by Khan et al. (2019) and Moreira et al. (2020).

3.2.3 Flexural strength

The flexural strength was analyzed considering the ASTM C78 (2022) standard, whose findings are indicated in Figure 3e. In all the cases studied, the results denote a reduction in flexural strength in relation to standard concrete (sample M1), however, when evaluated in reference to the minimum design strength of 3.55 MPa, a significant increase is evident in all samples, with the maximum increase being 24.51 %, which corresponded to sample M2 for 5.00 % of MEVA.

On the other hand, there is evidence that the size variability of MEVA residues show little or no difference in the alteration of flexural strength, but the amounts added to the concrete do have an influence, as pointed out by Farhoud et al. (2019) and Khan et al. (2019). Likewise, the decreases produced in the present investigation are explained due to the fact that all the properties analyzed maintain the same pattern of reduction both in the compressive strength, tensile strength and flexural strength with respect to the control sample, whose main determining factor is the effect produced by the increase in the dose of MEVA on the density of concrete and therefore on the mechanical properties in its hardened state.

3.2.4 Modulus of elasticity

The modulus of elasticity was evaluated in accordance with the ASTM C469 (2022) standard, the results of which are shown in Figure 3f. The findings indicate that, like the other mechanical properties previously analyzed, there is also a considerable influence of MEVA on the modulus of elasticity of concrete in its hardened state, especially for the MEVA percentage of 20.00 %, since the modulus reached by sample M5 decreased by 31.66 % compared to the modulus of standard concrete (sample M1). Despite this, the M2 sample complied with the modulus requested for structural concrete, since its value reached 21.77 GPa, that is, it increased by 2.11 % in relation to the required modulus of elasticity of 21.32 GPa.

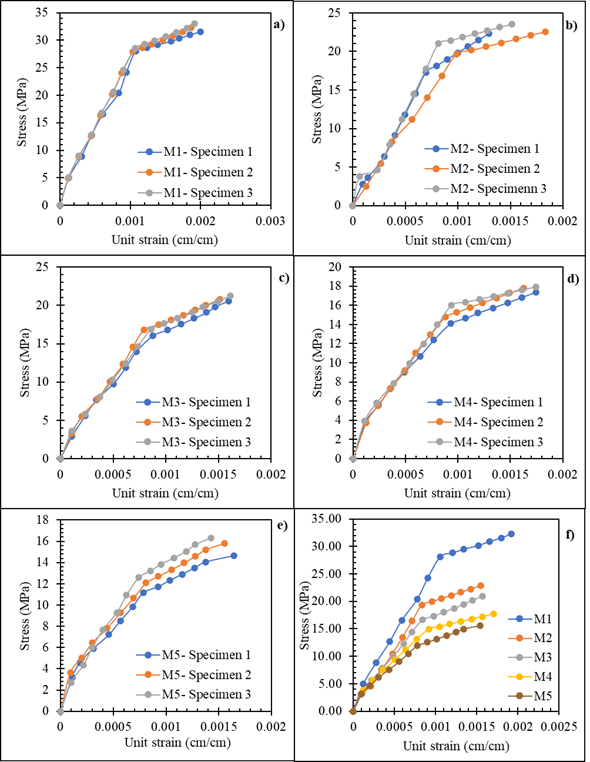

Figure 4 shows the unit stress-strain curves of the concrete obtained from the modulus of elasticity at the age of 28 days, in effect it is the product of the readings of 3 specimens for each experimental treatment; in addition, the graphs of their final averages for each treatment were developed as shown in Figure 4f.

3.3 Statistical analysis

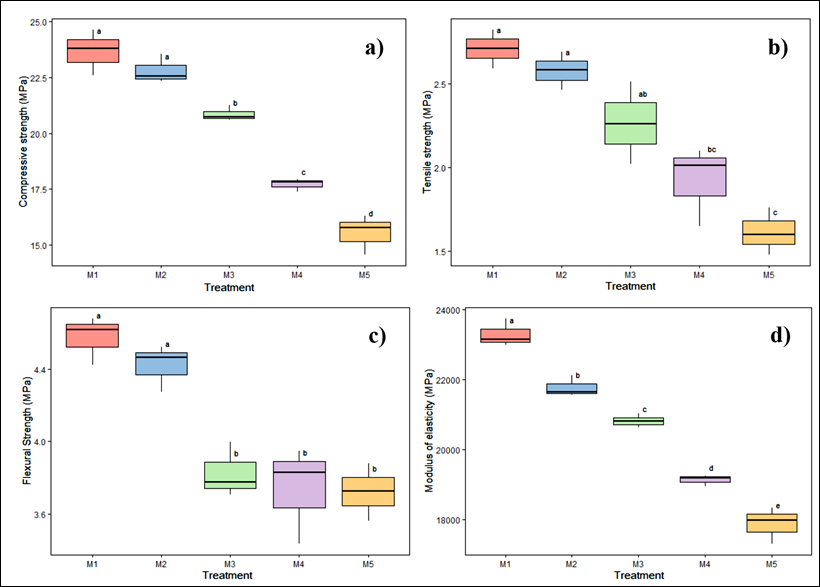

The statistical analysis was based on the evaluation of the four mechanical properties of concrete considered in the present investigation, as shown in Figure 5a (compressive strength), Figure 5b (tensile strength), Figure 5c (flexural strength) and Figure 5d (modulus of elasticity).

As indicated in Figure 5a, a p-value of significance associated with the one-way Anova test for compressive strength was obtained, a value less than 0.05 (p = 2.5 × 10-7 < 0.05). So it can be affirmed that there is a significant difference between the effects of the treatment without any addition of MEVA (sample M1), compared to concrete with 5.00 % of MEVA inclusion (sample M2).

Figure 3 Physical properties of concrete: a) slump; b) unit weight; and mechanical properties of concrete: c) compressive strength; d) tensile strength; e) flexural strength and f) modulus of elasticity

Figure 4 Unit stress-strain curves of the mixtures: a) M1; b) M2; c) M3; d) M4; e) M5 and f) Average of stress-strain curves obtained

Both treatments made it possible to maximize this strength, which was identified by Tukey's multiple comparison test, establishing that the compressive strength achieved with 5.00 % of MEVA in the concrete was better than the other doses, but not being superior to the concrete strength without any incorporation of MEVA.

Also, in Figure 5b, corresponding to tensile strength, the one-way Anova test was applied, which presented a p-value of significance less than 0.05 (p = 1.16 × 10-4 < 0.05), that allowed us to know that there is a significant difference between the effects of these strength. In addition, Tukey's multiple comparison test made it possible to identify the optimal dose of MEVA in the concrete in relation to the strength without including MEVA, since statistically, the tensile strength with 5.00 % of MEVA in the concrete (sample M2) was better in relation to the other percentages, but not higher than the standard concrete (sample M1).

Then in Figure 5c, corresponding to the flexural strength, the p-value of significance of one-way Anova test, exhibited a value less than 0.05 (p = 2.3 × 10-4 < 0.05), that is, the effects of the MEVA incorporations presented significant differences. Likewise, these findings are supported by Tukey's multiple comparison test, since the concrete without any addition of MEVA (sample M1) was slightly higher than the concrete with MEVA at 5.00 % (sample M2).

Finally, in Figure 5d, corresponding to the modulus of elasticity, the one-factor Anova test presented a p-value less than 0.05 (p = 2.3 × 10-8 < 0.05), therefore the equality hypothesis is rejected, while Tukey's multiple comparisons test allowed us to identify that sample M1, corresponding to concrete without any addition of MEVA, had a significantly higher modulus of elasticity than concrete with 5.00 % of MEVA.

4. CONCLUSIONS

This document presents important experimental findings of an applied type of research, which demonstrates the great potential of using MEVA residues from the footwear industry to produce structural concrete. Based on this, the following conclusions can be extracted:

The decrease in the settlement and the unit weight of the concrete mixture during its fresh state, were affected mainly with doses higher than 10.00 % of MEVA, so an acceptable option to help improve these conditions would be using some additive of the plasticizer type. since it would be possible to greatly reduce the variation of the water and therefore the w/c ratio.

It was possible to establish that there is a gradual decrease in all the mechanical properties of concrete, as the doses of MEVA are increased. Despite this, the mechanical performance showed significant increases in the compressive strength with 8.81 %, in the tensile strength with 22.86 %, in the flexural strength with 24.51 %, and in the modulus of elasticity with 2.11 %, using the addition of 5.00 % of MEVA, compared to the strength required of 21.00 MPa at 28 days, for the above, said incorporation is the optimal and can be used in the elaboration of a structural concrete, likewise, these results were demonstrated by means of the respective statistical.

It is recommended for future studies the use of pozzolanic materials as an addition or replacement of aggregates in order to improve the integral behavior of structural concrete with MEVA, it is also necessary to investigate the internal microstructure and durability of concrete under these conditions, in order to guarantee the safety and functionality to produce concrete of this category.