1. INTRODUCTION

The ‘mortiño’ (Vaccinium floribundum Kunth) is a native wild fruit from the Ecuadorian highland moors. In Ecuador, cultivations do not exist to be marketed. It grows in small allotments where the indigenous communities perform the manual collection twice a year in July-August and October-November (Popenoe et al., 1989, p, 218). Its main use is for the preparation of the “colada morada”, (a hot fruit drink with different fruits and spices), which is consumed in November in the “Day of the deceased’s”. The ‘mortiño’ is a source of polyphenols, anthocyanins, β-carotene, and vitamin C, minerals as potassium, zinc and dietary fiber (Vasco et al., 2009, p. 8275).

These compounds protect to the humans of certain degenerative illnesses as cancer, Alzheimer, diabetes and coronary illnesses. Cardiovascular diseases (Pascual y Sánchez, 2008, p. 282). The blueberries are used in the food industry, due to the phenolic compounds present in these fruits have anti-microbial and antioxidant effects (Heinonen, 2007, p. 688). Based on above-mentioned, it is important to promote the consumption of this fruit as functional food or as an ingredient of drinks and products like dry fruits.

On the other hand, the drying process allows preserving the foods. The conditions of the pretreatments like concentrations of the immersion solutions, exposition time should be determined and selected considering treatments that allows to save energy, the minimum drying time and to have the maximum retention of phenolic compounds.

It has been demonstrated that in fruit processing, the oxygen presence and high temperatures (90 ºC) accelerate the destruction of the anthocyanins, meanwhile that if the process was performed in a range from 40 to 60 ºC it is not affected its conservation significantly (Macheix et al., 1990, p. 316; Routray y Orsat, 2011, p. 306). In order to increase the drying speed approximately to twice as much in the production of grapes happens, cold bath of solution of potassium carbonate and ethyl oleate are used. The ester changes the structure of the wax in the peel of the fruits and it reduces its surface tension; the salt, on the other hand, allows the formation of a stable emulsion (Christensen y Peacock, 2000, p. 213). By means of the sulfidation pre-treatment, it is possible to inactivate the enzymes, especially the polyphenoloxidase which is the causing of the oxidation of the anthocyanins (Macheix et al., 1990, p. 1 990; Clifford, 2000, p. 1 065).

The present work had as objective to study the effect of pre-treatments of drying ‘mortiño’ as regards to the drying speed and the retention of total content of soluble polyphenols and anthocyanins. A stability test was performed on the dried ‘mortiño’, stored to different storage conditions, humidity and temperature. The fruits were also dried in a hybrid solar dryer to the best conditions of the pre-treatments.

2. MATERIALS AND METHODS

2.1 Materials

In this work was used fresh ‘mortiño’ (Vaccinium floribundum Kunth) at organoleptic ripeness stage. It was acquired in Pedregal located in Machachi in Mejía County. The fruits were disinfected in a water solution chlorinated with 100 ppm. The disinfected fruits were washed in a continuous rotational washer for fruits with bars, brand Sinclair Scott Co. The washed ‘mortiño’ was packed in polyethylene cases in portions of approximately 3 kg and stored at 5 ºC.

2.2 Physical-chemical characterization of the raw material and of processed

For the physical-chemical characterization of the raw material, fruits were freeze dried in batches of 2 kg.

2.2.1 Methods of physical-chemical characterization of the raw material

In the fresh fruit, it was determined: pH, ashes, humidity and acidity titratable by the method AOAC (2007). In the freeze-dried ‘mortiño’ samples was determined a total content of soluble polyphenols by means of the method of Folin-Ciocalteu (Slinkard y Singleton, 1997). Total anthocyanins were determined by applying the method described by Giusti (Giusti y Wrolstad, 2001). Proteins and ether extract by the method, (AOAC (2007), galacturonic acid according to (Theander et al., (1991)), minerals (K, Ca, Mg, Cu, Zn, Fe) by the method (DECAB (2001)), total dietetic fiber by the method (Asp et al. (1983)), sugar contents (DECAB, 2004a), vitamin C (DECAB, 2004b) and the contents of carotenoids (Petterson y Jonsson, 1990) by HPLC.

2.2.2 Physical-chemical characterization of the processed product

In the dried ‘mortiño’ samples, soluble polyphenols were quantified, total anthocyanins, humidity, minerals, total dietary fiber and profile of sugars, vitamin C, and organic acids. In order to quantify the percentage of retention of phenolic compounds in the dried ‘mortiño’ in a stove and in a hybrid solar dryer, it was considered as 100 % the quantity in the freeze-dried ‘mortiño’.

2.3 Temperature effect and airflow in the drying process in a tray dryer

The ‘mortiño’ was dried in a stove (Freas model 625-A) with a variation of airflow, provided of four perforated aluminum trays of dimensions 45 x 42.5 cm. In order to study the effect of the temperature and airflow on the content of soluble polyphenols, anthocyanins content and drying time a factorial design was applied 22. The temperature was varied between 40 and 50 ºC and the flow rate between 0.24 and 0.40 m3/s of air in 2 levels. Each experiment was carried out for duplicated. The statistical analysis was carried out in the program STATGRAPHICS CENTURION.

2.4 Effect of the pre-treatment of the immersion bath on the drying process

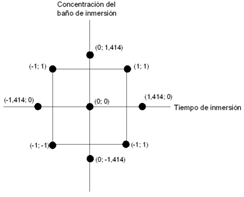

The pre-treatment was applied to the fresh ‘mortiño’, to determine the effect of the composition of the immersion bath and the exposure time on the content of soluble polyphenols, anthocyanins content and time of drying. It was applied for this purpose an experimental design 22 with axial points; in the Figure 1, the sorted corresponding pairs to the samples are presented. The conditions are shown for the nine samples carried out in the Table 1.

Table 1. Conditions of concentration of the bath and time of immersion for each sample

| Coded value | Concentration of K2CO3 Concentration of ethyl oleate (P/P)-(V/V) | Time of immersion (min) |

|---|---|---|

| (1;1) | 2.22-1.78 | 4.6 |

| (1;-1) | 2.22-1.78 | 2.4 |

| (-1;-1) | 0.88-0.72 | 2.4 |

| (-1;1) | 0.88-0.72 | 4.6 |

| (0; 0) | 1.55-1.25 | 3.5 |

| (0;1.414) | 1.55-1.25 | 5.0 |

| (1.414; 0) | 2.50-2.00 | 3.5 |

| (0;-1.414) | 1.55-1.25 | 2.0 |

| (1.414; 0) | 2.50-2.00 | 3.5 |

The composition of the immersion bath was fixed to 2.5 % K2CO3 (W/W) – 2 % of ethyl oleate (V/V) and 0.6 % K2CO3 (W/W) and 0.5% of ethyl oleate (V/V); the time of exposition was between 2 and 5 minutes. The treatment at the central point (0; 0) was repeated three times. The results were analyzed in the STATGRAPHICS CENTURION program.

2.5 Effect of the pre-treatment with sulfur dioxide on the drying process

The pre-treatment ‘mortiño’ was placed in a stainless steel chamber with a base of 60 cm and a height of 50 cm, the corresponding quantity of sulfur was burned. To analyze the influence of the sulfidation on the anthocyanins content and soluble polyphenols in the dehydrated ‘mortiño’, a factorial design was applied 22. The dioxide concentration of sulfur (1 000 and 2 000 ppm) and time of sulfidation (1 and 2 h) as variables of the process according to bibliographical information were selected. (Mujumdar, 1995, p. 647; Christensen y Peacock, 2000, p. 214).

2.6 Drying ‘mortiño’ in a hybrid solar dryer

The ‘mortiño’ with the best pre-treatments became dehydrated in a hybrid solar dryer. This consists of a solar collector of dimensions 180 x 70 cm, a chamber of drying of 60 x 70 x 100 cm, an automatic controller for the temperature, an electric resistance and two porous trays of plastic of dimensions 40 x 60 cm. The temperature in the chamber was 50 ºC and the airflow was provided with a fan that was applied to the equipment.

2.7 Tests of stability

The dried ‘mortiño’ with the best conditions of temperature, airflow and parameters of pre-treatments, underwent tests of stability. The dried fruits were stored during 2 months in a laminated and metalized multilayer film, to -17 ºC, 4 ºC and 25 ºC to 90% HR. The color was evaluated and the soluble anthocyanins, polyphenols and humidity were quantified.

3. RESULTS AND DISCUSSIONS

3.1 Physical-chemical characterization of the raw material and the finished product

In the Table 2 the characterization of the fresh fruit is presented (freeze-dried) and of the dried fruit as much in the stove as in the hybrid solar dryer. By means of the statistical study, it was determined that there was not found any statistically significant differs in the concentration of soluble polyphenols, anthocyanins and potassium in the dehydrated ‘mortiño’ with pre-treatments by means of the techniques studied in comparison to the freeze-drying.

3.2 Effect of the temperature and flow of air in a dryer of trays in the drying process

3.2.1 Effect of the temperature and airflow regards to the time of drying

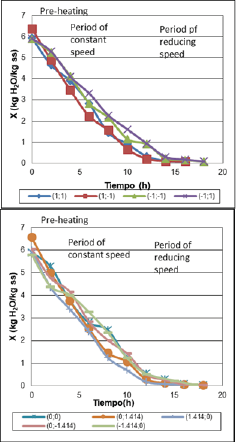

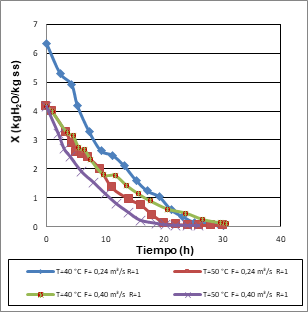

In the Figure 2 the curves of dehydration are shown. The three periods of dehydration can be observed; for the curve of 40 ºC and 0.24 m3/s, 0.24 m3/s, the period of warm-up lasted around 5 h, the period of constant speed 20 h and the period of falling speed 5 h. One can observe that the process is extensive since the diffusion of the vapor of water is hindered by the nature of the peel of the fruits, which does not have enough capillary that allow the exit of the water.

Table 2. Chemical characterization of the fresh fruit and the dried ‘mortiño’

| Units | Fresh fruit | Dried fruit, dehydrated en heating stove* | Dehydrated fruit en hybrid solar dryer* | |

|---|---|---|---|---|

| Humidity2 | g/100 g PF | 83.47 ± 3.02 | 5.01 ± 0.71 | 5.66 ± 0.13 |

| Proteins3 | g/100 g PF | 0.60 - 0.64 | - | - |

| Ashis3 | g/100 g PF | 0.33 - 0.34 | - | - |

| Dietetic fiber, total | g/100 g PF | 2.39 | 3.83 | 4.38 |

| Extract of ethereal3 | g/100g PF | 0.79 ± 0.04 | - | - |

| pH4 | 2.61 ± 0.06 | - | - | |

| Titratable acidity | g Citric acids /100 g PF | 7.72 ± 0.08 | - | - |

| Galacturonic4 acids | g/100 g PF | 0.52 ± 0.04 | - | - |

| Soluble3 sugars | ||||

| Fructose | g/100 g PF | 4.55 ± 0.06 | 4.12 ± 0.13 | 3.83 ± 0.21 |

| Glucose | g/100 g PF | 2.96 ± 0.04 | 2.97 ± 0.11 | 2.73 ± 0.13 |

| Organic3 acids | ||||

| Citric acid | mg/100 g PF | 1 185.99 ± 74.53 | 1 113.79 ± 38.58 | 949.57 ± 79.06 |

| Malic acid | mg/100 g PF | 451.52 ± 14.96 | 436.45 ± 31.45 | 417.10 ± 9.80 |

| Minerals3 | ||||

| Ca | mg/100 g PF | 26.74 ± 9.37 | 27.53 ± 3.14 | 26.64 ± 0.41 |

| K | mg/100 g PF | 58.49 ± 6.74 | 62.30 ± 1.12 | 52.03 ± 4.83 |

| Mg | mg/100 g PF | 15.13 ± 1.73 | 17.90 ± 0.64 | 16.99 ± 0.89 |

| Cu | mg/100 g PF | 0.06 ± 0.01 | 0.01 ± 0.00 | 0.02 ± 0.00 |

| Zn | mg/100 g PF | 0.84 ± 0.13 | 0.20 ± 0.00 | 0.18 ± 0.01 |

| Fe | mg/100 g PF | 0.49 ± 0.08 | 0.40 ± 0.10 | 0.26 ± 0.04 |

| Na | mg/100 g PF | 1.66 ± 0.05 | 1.74 ± 0.17 | 1.69 ± 0.14 |

| Antioxidant components | ||||

| Vitamin C3 | mg/100 g PF | 1.27 ± 0.02 | 0.96 ± 0.01 | 1.19 ± 0.04 |

| β-caroten3 | mg/100 g PF | 0.13 ± 0.00 | - | - |

| Soluble polyphenols | mg/100 g PF | 729.49 ± 112.851 | 960.72 ± 8.694 | 960.69 ± 33.744 |

| Anthocyanins | mg/100 g PF | 268.67 ± 33.652 | 439.56 ± 10.934 | 396.21 ± 6.254 |

1Media ± DE (n=9), 2Media ± DE (n=10), 3Media ± DE (n=2), Media ± DE (n=3) * Characterization of ‘mortiño’ from Cotacachi province in Imbabura; PF= Peso Fresco (=Fresh weight)

Figure 2. Graphs of drying for different established conditions when drying in dry base. a: warm-up, b: period of constant speed and c: period of falling speed

By means of the graphs of drying, the time of drying was determined in the one that the product has 5% of humidity approximately, these values are presented in the Table 3.

Table 3. Dehydration time of ‘mortiño’ with the established conditions of temperature and airflow

| Temperatura(ºC) | Flow(m3/s) | Time of drying Repetition 1(h) | Time of drying Repetition 2(h) |

|---|---|---|---|

| 40 | 0.24 | 30 | 30 |

| 50 | 0.24 | 24 | 20 |

| 40 | 0.40 | 28 | 31 |

| 50 | 0.40 | 24 | 24 |

Generally, to dehydrate blueberries lingering time is required, due to the waxen cuticle of these fruits, because the wax controls the speed of diffusion of water during the dehydration. It is analyzed that the restrictive factor in the dehydration is the mass transfer (Casp and April 2003, p. 337; Ibarz et to the one, 2000, p. 99; Bhat et to the one, 2009, p. 441).

According to the ANOVA the temperature has statistically significant influence (p$<0.05) on the time of drying. The airflow in the studied levels did not influence significantly on the same one. The higher temperature the less time of drying since the diffusion of vapor of water is directly proportional to the temperature (Ibarz et to the one., 2000, p. 95).

3.2.2 Temperature effect and airflow on the retention percentage of anthocyanins and soluble polyphenols in the dehydrated ‘mortiño’

In Table 4 can be observed that there is bigger percentage retention of anthocyanins on low temperature and airflow. This is due to that the anthocyanins are destroyed logarithmically with the increment of the temperature (Macheix et al., 1990, p. 314; Routray y Orsat, 2011, p. 306) and when there is oxygen presence in the system, the anthocyanins demeans due to the enzymatic browning (Macheix et al., 1990, p. 295).

Table 4. Percentage of anthocyanins retention to the different conditions of temperature and airflow

| Temperatura(ºC) | Flow(m3/s) | Retention Iteration 1(%) | Retention Iteration 2(%) |

|---|---|---|---|

| 40 | 0.24 | 54.2 | 45.4 |

| 50 | 0.24 | 39.1 | 39.9 |

| 40 | 0.40 | 34.6 | 35.0 |

| 50 | 0.40 | 34.2 | 36.6 |

According to the ANOVA the airflow had statistically significant influence (p<0.05) on the anthocyanins content. Less temperature and airflow will result in higher retention percentage.

In the Table 5, the obtained results of the percentage of retention of soluble polyphenols are presented in the dehydrated ‘mortiño’. It is observed that these values are relatively high, near to 100% in relation to the content in the freeze-dried ‘mortiño’.

Table 5. Percentage of retention soluble polyphenols in dehydrated ‘mortiño’ under different temperature conditions and airflow

| Temperatura(ºC) | Flow(m3/s) | Retention Replica 1(%) | Retention Replica 2(%) |

|---|---|---|---|

| 40 | 2 | 97.8 | 97.7 |

| 50 | 2 | 94.1 | 93.9 |

| 40 | 4 | 99.9 | 80.9 |

| 50 | 4 | 92.2 | 98.0 |

According to the statistical analysis the flow of air and the temperature do not have it influences statistically significant (p<0.05) on the percentage of retention of soluble polyphenols. It could be due to that in comparison to the anthocyanins, the polyphenols is composed whose structure is more resistant to the temperature and the oxygen (Joshi et al., 2009, p. 456).

Statistically drying conditions of 40 ºC and 0.24 m3/s airflow were selected in the dryer of trays.

3.3 Effect of the pre-treatment of immersion bath on the drying process

3.3.1 Effect of the pre-treatment of immersion bath about the time of drying

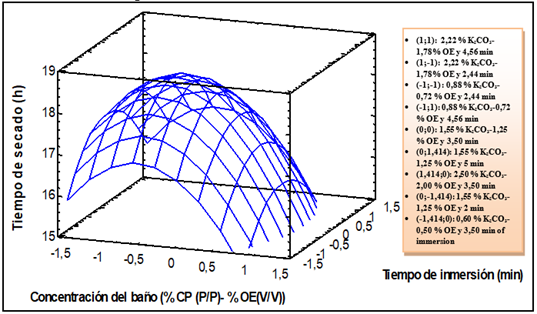

The Figure 3 (to and b) it is shown the curves of ‘mortiño’ dehydration to the different concentrations of the immersion bath.

It can be observed that the time when it arrives to the established humidity (5 to 6%) is around 50% less than the drying without pre-treatment according to the curves of dehydration that are presented in the Figure 2. The K2CO3 and the ethyl oleate modify the structure of the present waxes in the shell of the fruit and it facilitates the diffusion of the vapor of the water (Christensen and Peacock, 2000, p. 213). According to the ANOVA the concentration of the bath is a variable that has statistically significant influence (p<0.05) about the drying time, in such a way that the more concentration results in less time of drying. In Figure 4 illustrates the response surface of maximum time of drying. Inside this area is the coordinate point (0; 0) that corresponds to the conditions of concentration of the bath of 1.55% K2CO3, 1.25% ethyl oleate and 3.5 min immersion. The shortest drying time can be found near the point code (1; 1), that corresponds to the conditions of concentration of the bath of 2.22% K2CO3, 1.78% ethyl oleate, and 4.56 min immersion.

3.3.2 Effect of the pre-treatment in immersion bath on the percentage of retention of anthocyanins in the freeze-dried ‘mortiño’ with the pre-treatment

The percentages of retention of anthocyanins in the freeze-dried fruits with the pre-treatment are presented in Table 6. Less percentages than 100% are observed, is due to that the anthocyanin is more stable between acid (pH<3) than between neutral or alkaline (Pascual and Sanchez, 2008, p. 282)

Table 6. Content of anthocyanins in the freeze-dried ‘mortiño’ with pre-treatment in immersion bath

| Valor Codified | Anthocyanins freeze-dried ‘mortiño’ with treatment (mg/100 g PF1) | Retention of anthocyanins freeze-dried ‘mortiño’ with treatment(%) |

|---|---|---|

| (1;1) | 161.9 | 63.0 |

| (1;-1) | 158.4 | 61.6 |

| (-1;-1) | 124.6 | 48.4 |

| (-1;1) | 129.1 | 50.2 |

| (0;0)1 | 256.2 | 99.2 |

| (0;0)2 | 221.7 | 85.8 |

| (0;0)3 | 223.0 | 86.3 |

| (0; 1.414) | 115.0 | 44.7 |

| (1.414; 0) | 140.8 | 54.8 |

| (0; -1.414) | 230.6 | 89.7 |

| (-1.414; 0) | 124.8 | 48.5 |

1PF = Peso Fresco (Fresh weight)

Figure 4. Response surface to study the influence of concentration of the immersion bath and time regards to the time of drying. CP= Potassium Carbonate; OE= Ethyl Oleate

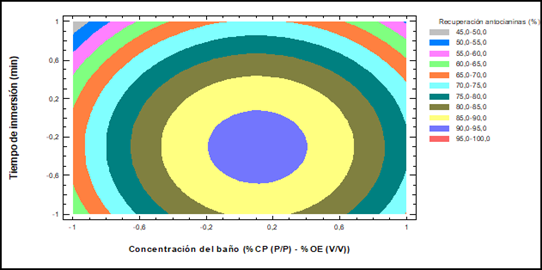

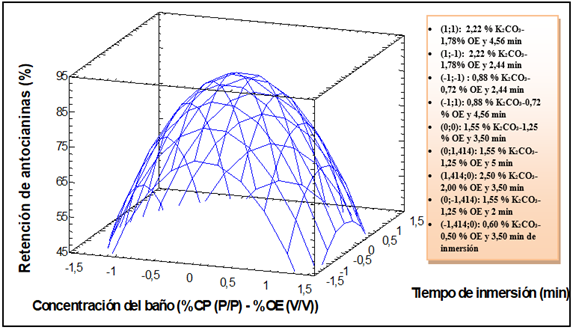

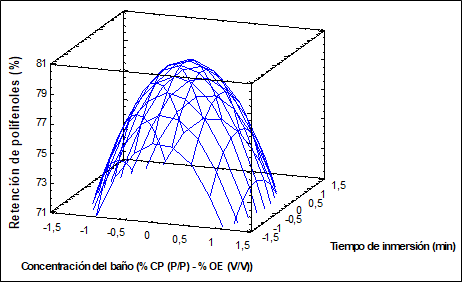

According to the ANOVA the quadratic term of the concentration of the immersion bath influences statistically (p<0.05) on the percentage of retention of anthocyanins in the freeze-dried ‘mortiño’ with the pre-treatment. In the Figure 5, the response surface is shown. One can observe an area of maximum retention percentage, in which is the point of coordinated (0;0) that corresponds to concentration of the bath of 1.55% of K2CO3-1.25% of ethyl oleate and 3.5 immersion min, the same one that is the central point of the outlined experimental design. The Figure 6 corresponds to the graph of contours. It is evidenced that the maximum percentage of anthocyanins retention is located in the region among the coordinates -0.2 (2.09% of K2CO3-1.67% of ethyl oleate) and 0.4 (1.82% of K2CO3-1.46% of ethyl oleate) for the concentration of the bath, for the time of drying among the coordinates -0.7 (4.3 min) and 0.1 (3.6 min).

Figure 5. Response surface to the study of the influence of the concentration of the bath and time of immersion on the percentage of retention of anthocyanins CP = Carbonate of potassium; OE = ethyl Oleate

3.3.3 Effect of the pre-treatment of immersion bath on the percentage of retention of anthocyanins and soluble polyphenols in the dehydrated ‘mortiño’

The results of the percentage of anthocyanins retention and soluble polyphenols are presented in the Table 7. The percentages of retention of anthocyanins are around 50% for all the experimental conditions. According to the statistical analysis, the concentration of the bath and the time of immersion do not influence (p<0.05) on the concentration of anthocyanins in the dehydrated fruit.

It is also observed that there is difference in the percentage of retention of soluble polyphenols depending on the concentration of the immersion bath. This indicates that these bioactive compounds are affected by the components of the immersion bath.

Table 7. Percentage of retention of anthocyanins and soluble polyphenols in the ‘Mortiño’, dehydrated in stove for each concentration of the bath and time of immersion

| Codified Value | Retention of Anthocyanins ‘mortiño’ dehydrated (%) | Retention of polyphenols ‘mortiño’ dehydrated (%) |

|---|---|---|

| (1;1) | 52.2 | 73.2 |

| (1;-1) | 52.9 | 74.8 |

| (-1;-1) | 44.4 | 71.3 |

| (-1;1) | 51.8 | 72.8 |

| (0;0)1 | 50.9 | 82.4 |

| (0;0)2 | 46.7 | 81.4 |

| (0;0)3 | 46.0 | 76.6 |

| (0;1.414) | 39.3 | 74.0 |

| (1.414; 0) | 42.4 | 68.0 |

| (0;-1.414) | 44.6 | 77.3 |

| (-1.414; 0) | 50.8 | 70.9 |

According to the ANOVA the quadratic term of the concentration of the immersion bath influences statistically (p<0.05) on the percentage of retention of soluble polyphenols in the dehydrated ‘mortiño’.

In the Figure 7 the estimated response surface is presented, one can observe an area of maximum percentage of retention of soluble polyphenols. Inside this area is found the point (0; 0), that is the central point of the outlined experimental design (22 with axial points) and it corresponds to the conditions of concentration of the bath of 1.55% of K2CO3–1.25% of ethyl oleate and 3.5 immersion min. Statistically the conditions of the bath and time of immersion of 1.55% K2CO3 was chosen (P/P) – 1.25% of ethyl oleate (V/V) and time of immersion of 3.5 min.

3.4 Effect of the pre-treatment with SO2 on the drying process

3.4.1 Effect of the pre-treatment of the sulfidation regards to the percentage of retention of anthocyanins

In the Table 8, the percentage of anthocyanins retention is presented in the dehydrated ‘mortiño’. One can observe that the retention percentage increased to 45% in relation to the dehydrated ‘mortiño’ without pre-treatment. This could be explained because the SO2 inactivates the enzyme polyphenoloxidasa that is the causing of the oxidation of anthocyanins (Macheix et al., 1990, p. 311; Clifford, 2000, p. 1065).

Figure 7. Response surface to study the influence of the concentration of the bath and time of immersion on the percentage of retention of soluble polyphenols

By means of the statistical study it was determined that the concentration of sulfur has statistically significant effect (p<0.05) on the percentage of the retention of anthocyanins. Higher concentration of sulfur will result in more retention percentage.

3.4.2 Effect of the sulfidation pre-treatment on the percentage of retention of soluble polyphenols

The percentage of retention of soluble polyphenols is presented in the Table 9. One can observe that these percentages are near to 100%, this indicates that the sulfidation doesn't have effect on these compounds.

Table 9. Percentage of polyphenols retention in dehydrated ‘mortiño’ with pre-treatments

| SO2 (ppm) | Time of sulfidation (h) | Retention de Repetition 1(%) | Retention de Repetition 2(%) |

|---|---|---|---|

| 1 000 | 1 | 92.0 | 99.4 |

| 2 000 | 1 | 97.4 | 98.6 |

| 1 000 | 2 | 84.2 | 99.2 |

| 2 000 | 2 | 98.8 | 98.1 |

Statistically the concentration of SO2 of 2 000 ppm and 2 h were chosen to expose the fruit.

3.5 Comparison between processes

In the Table 10, the final results of the concentration of soluble polyphenols and total anthocyanins are presented in the dehydrated ‘mortiño’ and time of drying, for each one of the carried out processes. As you, one can observe in the dehydrated product in stove without pre-treatments the percentage of retention of anthocyanins in relation to the freeze-dried is of 54.2%. While in the drying of ‘mortiño’ with pre-treatments to the same conditions, 98.2% of retention was reached. This was achieved because due to the sulfidation pre-treatment the enzymes polyphenols oxidizers could have been deactivated (Macheix et al., 1990, p. 311; Clifford, 2000, p. 1065). In the hybrid solar dryer, it was obtained dehydrated ‘mortiño’ with 88.5% of retention. With pre-treatment of immersion bath, it was possible to diminish 12 hours of drying in relation to the process without pre-treatment.

Table 10. Comparison results among the processes of ‘mortiño’ dehydration

| Characteristics | DESPT | DECPT | DSCPT |

|---|---|---|---|

| Anthocyanins (mg/100 g PF) | 150.4 | 439.6 | 396.2 |

| Polyphenols (mg/100 g PF) | 573.9 | 960.7 | 960.7 |

| Time of drying | 30 h | 18 h | 5 days |

| Retention Anthocyanins (%) | 54.2 | 98.2 | 88.5 |

| Retention Polyphenols (%) | 97.8 | 99.7 | 99.7 |

DESPT = Dehydrated in oven sin pre-treatmentDECPT = Dehydrated in oven con pre-treatmentDSCPT = Dehydrated en hybrid solar dryer with pre-treatment

3.6 Test of stability

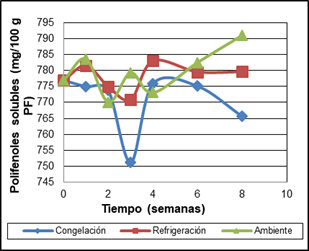

The change of the concentration of the soluble polyphenols with the storing time is presented in the Figure 8. As it is observed so much for the conditions of freezing storage (-17 °C), refrigeration (4 °C) and atmosphere (25 °C; 90% HR), the concentration of polyphenols oscillates between 751 and 791 mg/100 g PF. Decrease of concentration of polyphenols is not evidenced in the storage time, in this study.

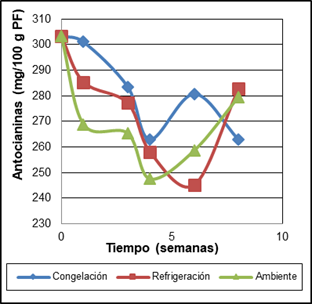

In the Figure 9, the variation of the concentration of anthocyanins is shown with the storage time. It can be observed that the anthocyanins gets lost with the time, because the presence of bioactive component in the ‘mortiño’, which is the most sensitive to the time and storage, conditions (temperature and humidity) (Macheix et al., 1990, p. 313).

Table 11 shows, the kinetic parameters of the stability of dehydrated ‘mortiño’.

Table 11. Kinetic parameters of the stability of the ‘mortiño’ dehydrated in stove with pre-treatments

| Parameter | Value |

|---|---|

| Constant of velocity k (week-1) | |

| Freezing ( -17 ºC) | 0.0343 |

| Refrigeration ( 4 ºC) | 0.0345 |

| Environment (25 ºC y 90 % HR) | 0.0419 |

| Frequency factor k' (week-1) | 0.1440 |

| Activation energy de E (KJ/mol) | 31.200 |

| Time of usefulness of the product by storing in 18 ºC | 4 months y 11 days |

In the three storage conditions the humidity increases. This can be due to the characteristic properties of permeability of the used packing.

It was determined that the initial color of the ‘mortiño’ dehydrated in a stove with pre-treatments was N99C40M50 (N = black, M = Magenta y C = Cyan), what means that the dehydrated product presented a black-brown color. No change of color of the product was detected during the 2 months of storage.

4. CONCLUSIONS

In the dehydrated ‘mortiño’ in stove with 40 ºC and flow of air of 0.24 m3/s, showed the maximum percentage of retention of phenolics compound (54.2% anthocyanins and 97.8% of soluble polyphenols) in relation to the freeze-dried fruits.

The immersion of the ‘mortiño’ for 3.5 min in the bath with a concentration of 1.55% K2CO3 (P/P) – 1.25% of ethyl oleate (V/V), was possible to diminish the dehydration time 12 hours in the stove.

The pre-treatment of immersion bath evidenced that statistically has a determining effect on the percentage of retention of soluble polyphenols.

The sulfidation to the fresh fruits with 2 000 ppm of concentration of SO2 and 2 h of exhibition allowed to increase the percentage of retention of anthocyanins from 54.2% to 98.2%. The dehydrated ‘mortiño’ in the hybrid solar dryer conserved 88.5% anthocyanins in relation to the freeze-dried fruit.

The dehydrated ‘mortiño’ in stove and in the hybrid solar dryer, had a hard texture, but it does not present any strange flavor due to the pre-treatments.

The dehydrated ‘mortiño’ has a time of useful life of 4 months and 11 days.