1. Introduction

Currently in the Ecuadorian market, a variety of auto parts are offered, both in brand and origin, at the same time, they go hand in hand with the quality and cost of the spare part. The cost factor can be influential when making a decision, because customers decide to buy, considering the cheapest option, without considering the best option in safety or performance.

In the vehicle, two safety systems coexist: passive and active; the former are those that work at specific moments when their action is activated, for example, airbags and the anti-lock braking system (ABS) (Bosch, 2005). Meanwhile, active systems, such as the braking system, are always in operation, the main means of ensuring the safety of the occupants of the moving vehicle. The frictional heat generated on the surface of the brake disc can influence an excessive increase in temperature which, in turn, causes undesirable effects such as thermal elastic instability, premature wear, brake fluid vaporization and thermally excited vibrations (Belhocine, A. & Bouchetara, M., 2012). It is important to analyze the composition of the material, as well as the microstructure of the different brake discs in the national market to verify their performance capacity according to the design conditions.

The Metallurgical Engineering Department of the University of Santiago de Chile has carried out studies of premature wear and abnormal mechanical vibrations in brake discs based on their chemical composition, concluding that such failure is produced by residual stresses originated by the difference that exists in the material composition of the different areas of the disc. These stresses were relaxed during the friction process to which the disc was subjected during its service and were the cause of the deformation of its geometry. (Piña, 2008) (Tuckart, Molinari, Caso, & Prieto, 2014). This study indicates that in the process of casting the piece, there may be failures produced by differences in the composition of the material, that is, there is a possibility that pieces with these possible failures are marketed at a regional level (Rodrigues, 2004).

The materials of the brake discs are generally made of grey cast iron. The regulation that governs the different grades of grey iron for the automotive industry is the SAE J431 standard, which determines certain grades for the manufacture of brake discs and drums (Rodríguez, 2004). Within the methods to analyze the composition of a metallic alloy, by the type of material and part, a spark type spectrometry is considered (Piña, 2008).

This research, proposes a comparative analysis of brake disc material between original and alternate auto parts. Due to the large share of alternative parts offered by the market at considerably lower costs compared to the originals, a comparison of the different compositions and microstructures that could present these options was made and it was analyzed whether these factors could affect their operation.

2. Methodology

The research process is descriptive and experimental. This research analyzes three brake disc samples (A, B, C) from different manufacturing sources, using the ASTM E415-08 spectrometry test to establish the components of each sample and the metallography test under the ASTM A247-16A standard to establish the type of matrix and the graphical distribution.

2.1 Vehicle

In the case of Ecuador, the age of the vehicle fleet is led by 28.99 % of cars between 1-5 years and followed by 21.44 % of cars between 5-10 years (AEADE; 2018). The third brand in the market is Hyundai, surpassed by Chevrolet and Kia. For the study has been chosen Hyundai vehicle, model i10, year 2014, segment type A, considered an urban vehicle, low fuel consumption and high demand in the local market, in addition to being an imported model.

2.2 Brake disc

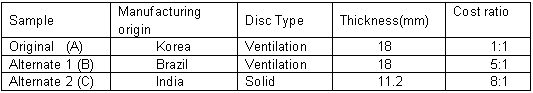

Table 1 describes the characteristics of the three brake disc samples identified as spare parts in the national environment.

2.3 Spectrometry test

The spectrometry test was performed under the standards of ASTM E415-08, is called standard test method for analysis of atomic emission vacuum spectrometry of carbon and low alloy steel. The test consists of inducing a current to an electrode and produce a spark in the disc, the same that would leave a spectrum of light, through the spectrum can be determined the composition of the material. The procedure was carried out in a standardized national laboratory. With spectrometric results, the carbon equivalent (CE) of each sample is calculated, using equation 1, for quantitative comparison of the samples.

𝐶𝐸 = %𝐶 + 0.31%𝑆𝑖 + 0.33%𝑃 − 0.027%𝑀𝑛 + 0.40%𝑆 (1)

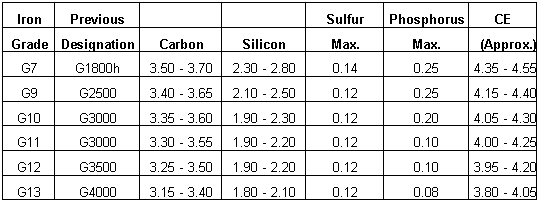

The carbon results of brake disc are compared with SAE J431 standard. In table 2, describes compositions for automotive gray iron according SAE J431 standard.

2.4 Metallographic test

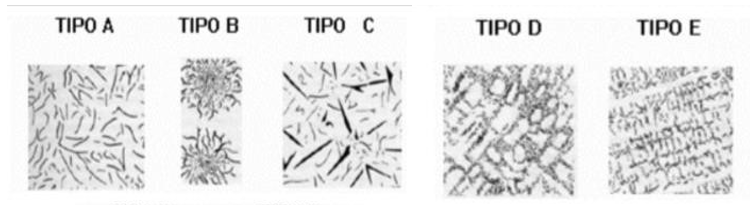

The metallographic test was performed under the ASTM A247-16A standard, which is called the standard test method for evaluating the microstructure of graphite in iron foundries. The matrix was analyzed under the microscope, with a resolution of 500X, and a resolution of 100X was used for the morphology and size of the flakes. The test piece result is then compared with the standardized standards in ASTM A247. Both major and minor elements have a direct influence on the morphology of flake graphite. The typical graphite shapes for flake graphite are shown in Figure 1.

In figure 1, Type A graphite is found in inoculated irons cooled with moderate rates. In general, it is associated with the best mechanical properties, and cast irons with this type of graphite exhibit moderate undercooling during solidification. Type B graphite is found in irons of near-eutectic composition, solidifying on a limited number of nuclei. Large eutectic cell size and low undercoolings are common in cast irons exhibiting this type of graphite. Type C graphite occurs in hypereutectic irons as a result of solidification with minimum undercooling. Type D graphite is found in hypoeutectic or eutectic irons solidified at rather high cooling rates, while type E graphite is characteristic for strongly hypoeutectic irons. Types D and E are both associated with high undercoolings during solidification.

2.4.1. Metallographic Specimens

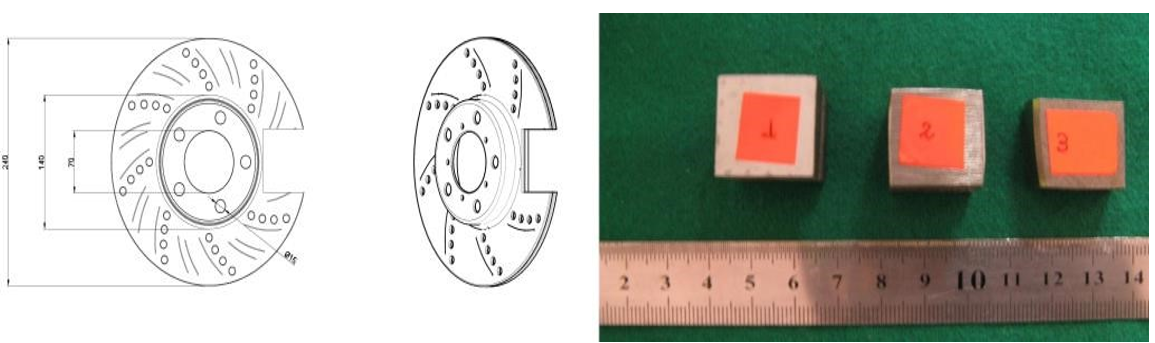

For the metallographic test, standardized specimens produced in the wear and failure laboratory are used, designated with numbers 1, 2 and 3, according to ASTM E-3 standards for each brake disc, for convenience, specimens to be polished for metallographic examination are generally not more than about 12 to 25 mm square, as shown in figure 2. Specimens embedded in plastic to protect them from damage and to provide a uniform format for automatic preparation.

For each test it was necessary to machine a 2x2 test tube. The test pieces were taken from the braking track, as shown in figure 2. The selection of test specimens for metallographic examination is extremely important because, if their interpretation is to be of value.

3. Results

3.1 Spectrometry of brake disc test pieces

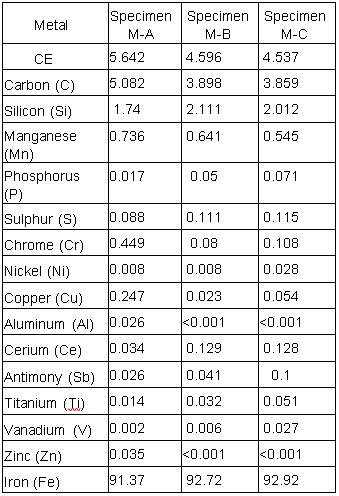

The results of the metal element spectrometry for each specimen are shown in Table 3.

Source: Extractive Metallurgy Laboratory EPN.

The test detects 15 components in each sample, with variations in value for each one. For materials with applications for brake discs and drums, a minimum of 3.4 % carbon content and a pearlitic microstructure is required, according to the grades of grey iron proposed by the SAE J431 standard. For each sample analyzed, this requirement is met, however, sample A presents 23 % and 24% more carbon than samples B and C, respectively.

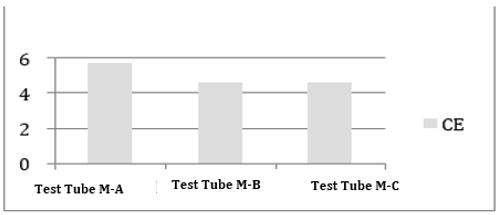

With regard to the influence of the composition on the microstructure of the material, the carbon equivalent (CE) plays a large role in the distribution and size of the graphite flakes, as well as in the matrix, which gives certain characteristics to the brake disc material. The results for carbon equivalent are shown in Figure 3.

In terms of the composition of the material, between samples B and C, they offer no major difference, however, there is a clear difference with sample A. The carbon equivalent of sample A is 18 % and 20% higher than that of samples B and C, which has a significant influence on the microstructure, since a higher carbon content leads to greater growth of the graphite flakes.

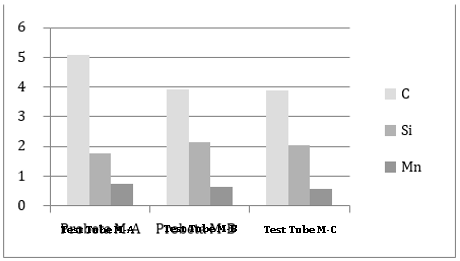

Five elements are involved in the calculation of the EC: carbon (C), silicon (Si), manganese (Mn), phosphorus (P) and sulphur (S). According to the SAE J431 standard, minimum compositions are established for five elements, specimen’s compositions are compared in the figure 4.

Carbon and silicon are the most influential elements in the formation of graphite, silicon acts as a graphitizer, inhibiting carbon so that it does not combine with another element to form graphite flakes, while manganese acts as a stabilizer of carbides(Askeland,2017).

The specimen of sample A, having a higher carbon and 17 % less silicon in relation to samples B and C, allows the brake disc A, to generate a higher growth of graphite flakes.

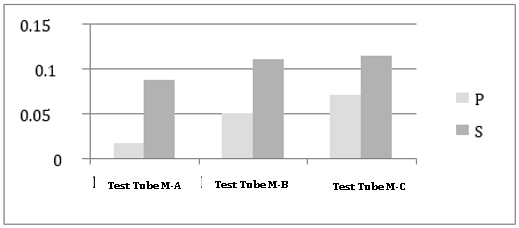

Both sulphur and phosphorus are found in proportions of less than 1 %, as shown in figure 5, because both in high proportions give fragility to the material, the sulphur has a function opposite to silicon acts as an antigraffiti and in high quantities over 1 % can cause cavitation.

In the case of Sulphur, as it is an anti-graffiticide, the sample A specimen has 23 % less in comparison to specimen’s B and C, giving the brake disc greater graffiti.

3.2 Metallography

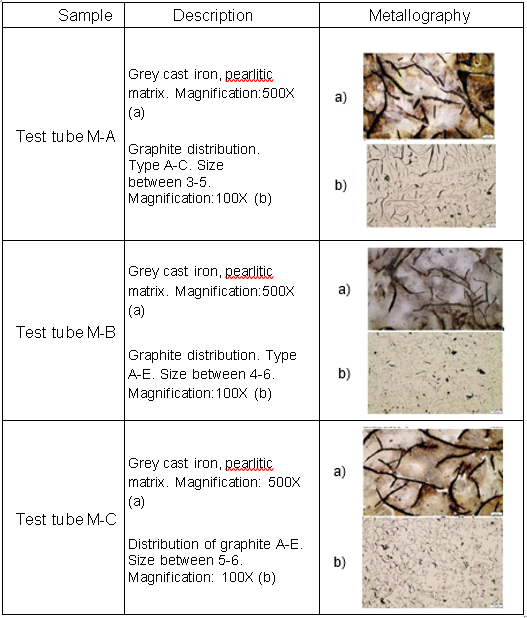

Table 4 shows the results of the metallographic test specimens. Each specimen has a pearlitic matrix, however, there is a different distribution and size of the flakes, which contribute with characteristics such as hardness and internal lubrication.

Comparing the different brake discs, it is found that sample A has a higher carbon content, which encourages more growth of the graphite flakes. The chemical composition of the material is involved in the growth of graphite flakes, the lower the EC, the smaller the grain size.

3.3 Discussion

According to, Gutierrez, N. & Vinueza Lozada, A. (2018), the existence of zinc reduces the heat flow between brake pad and disc, in sample A, a higher percentage of zinc is observed in relation to samples B and C, therefore, these samples would increase the working temperature during the braking action.

According to Kharate, N. & Chaudhari, S (2018), their study indicates a higher natural frequency oscillation in steel disc with respect to cast iron under similar operating conditions, therefore the existence of higher carbon equivalent, indicates a trend of oscillation in lower operation, such would be the case of the disc in sample A.

According to the studies by Canibano, E., Gonzalez, M. & del Amo, O. (2005) and Cherrez-Troya, M., Martínez-Gómez, J., Peralta-Zurita, D. & Llanes-Cedeño (2018), there are several factors to establish the appropriate conditions of a brake disc, but they are independent of the disc geometry, the blade geometry, the type of test, due to the robustness of the design methodology and the properties of the manufacturing material.

5. Conclusions and recommendations

The auto parts denoted as samples A, B and C, can be offered as brake disc replacement parts, sample A being the one with the best mechanical properties for the assigned function.

It was determined that the three samples of brake disc material, meet the specifications of SAE J431, which indicates the proposed carbon requirement for the manufacture of automotive brake discs and drums, must contain at least a 4.3 % carbon equivalent with pearlitic matrix.

Graphite flakes provide hardness and internal lubrication to the material, these two factors in a brake disc can increase the resistance to frictional wear, allowing a longer life in sample A.