Introduction

Water, a vital resource, faces threats from population growth and human activities, leading to scarcity. According to Fu et al. (2022), only 2.5 % of Earth's water is fresh, and a mere 0.4 % is usable, with this amount declining due to both natural and human factors. Rainwater harvesting systems offer a sustainable alternative, significantly reducing the consumption of potable water. However, the demand for water increases due to population growth and climate change, worsening the disparity in access to clean water and sanitation, especially between urban and rural areas (Meireles et al., 2022). Additionally, water-related diseases pose a significant public health threat, underscoring the need for a safe water supply for all (Delgado et al., 2024). By utilizing rainwater for non-potable activities like irrigation, car washing, or toilet flushing, the strain on potable water resources is lessened, as emphasized by Gómez-Monsalve et al. (2022)

Sultana (2022) examined the efficiency of rainwater tank systems, noting their dependence on factors such as tank size, local climate, and potable water demand. Using a simple daily water balance model, she assessed various tank sizes' performance in collecting rainwater from a 10 000 m2 roof area. Results showed tank sizes ranging from 130 to 630 m3, with a capture efficiency of 100 %. However, system reliability ranged from 2.8 to 37.75 % in dry and wet years, respectively. The optimal tank size fell between 180 and 240 m3, capturing over 64 % of roof runoff and thereby reducing urban water demand by about 10 %.

Simulation processes using computer-aided design (CAD) and computer-aided engineering (CAE) software have been refined for finite element method (FEM) resolution, enabling analysis without the need for experimentation or field tests (Tzotzis et al., 2020). Li et al. (2023) emphasize that the primary advantage of simulation is the rapid acquisition of results regarding the behavior of structural and dynamic elements. Computational numerical analysis facilitates the exploration of various scenarios, including changes in geometries, sections, or materials. Consequently, FEM is employed to analyze and predict the behavior of structures under various loads, allowing for the assessment of their strength, stability, and safety. This approach enables the calculation of stresses and deformations in each part of a structural element under different loading conditions, such as water pressure, wind loads, and seismic loads (Krok et al., 2023). Additionally, it allows for parametric analyses and design enhancements to minimize material usage while maintaining the tank's safety and functionality.

Through FEM, a comprehensive evaluation of the strength and stability of the support structure can be conducted, considering material properties and initial conditions. Martínez-Ramírez et al. (2022) explored methods to optimize the geometry of metal structures for practical applications using FEM. Designing structures for specific purposes requires consideration of safety, aesthetics, maintenance, economy, and environmental constraints. To address these requirements, geometries were analyzed before selecting appropriate materials and shapes, utilizing parametric design and finite element modeling. Parametric design and FEM are highlighted as crucial tools in this process, enabling engineers to establish permissible deflection limits and ensure a safety factor of approximately 2, which is indicative of a robust design. The significant contribution lies in applying a general-purpose program to a specific area of mechanics, facilitating the creation of efficient designs with reduced weight and cost in less time.

Dessales (2020) emphasize that designing a structure to elevate the rainwater storage tank offers a significant advantage over simply placing it on a surface, as it enhances water flow and pressure. Elevating the tank creates greater hydrostatic pressure, which facilitates water flow through pipes and outlet devices like faucets and showers (Duan et al., 2020). This is particularly advantageous in situations where a constant and uniform water pressure is required, thereby improving the efficiency and comfort of the rainwater harvesting system. Additionally, elevating the tank can create extra space underneath for other activities or to mitigate potential risks of water contamination. A study developed by (Ahmed et al., 2016) found that avian and possum fecal droppings can degrade the quality of roof-harvested rainwater due to zoonotic pathogens. The investigation evaluated a possum feces-associated marker using 210 samples from Australia, finding high sensitivity and specificity, 0.90 and 0.95, respectively. Possum samples had higher marker concentrations compared to non-possum samples. Testing tank water samples revealed significant fecal contamination, hence the recommendation is disinfecting tank water, especially for potable use, by demonstrating the effectiveness of microbial source tracking markers in identifying fecal contamination sources in rainwater tanks.

Liu et al. (2020) point out that utilizing CAD/CAE software tools for designing and analyzing support structures can significantly reduce costs and time associated with physical testing and prototyping. Erazo-Arteaga (2022) conducted a review of computer-aided design, manufacturing, and engineering in Latin America, demonstrating its application in various fields such as machine design, aerial vehicles, medicines, and human prostheses. Despite advancements, effective utilization of these tools requires training, and cost can pose a barrier for small and medium-sized enterprises as well as educational institutions. However, in recent years, the emergence of open-source CAD software options has expanded 3D modeling and rapid prototyping capabilities. These technological tools have streamlined engineering design processes, providing approximate real-world responses through computational numerical analysis.

Verma et al. (2024) conducted a design analysis of a 300-liter fuel tank for heavy vehicles. Their methodology involved CAD model optimization, numerical analysis setup, and experimental validation. Simulations unveiled stress distribution, deformation behavior, and fluid dynamics, with experimental tests confirming numerical predictions, displaying a general error of less than 5 %. Areas for design improvement were pinpointed, including reinforcing stress-prone regions and optimizing fluid flow dynamics. Results indicated stress concentrations in critical areas and deformation patterns under various loading conditions, with stress levels ranging from 160 to 200 MPa. The significance of weld strength was underscored, accompanied by improvement recommendations.

Arroba-Arroba et al. (2021) developed experimental processes and validated numerical analyses for alternative material structures repairing aircraft flight surfaces. Their focus was on evaluating polymer matrix composite materials for aircraft flight surface repairs. They employed the vacuum bagging process to produce homogeneous composites and tested reinforced specimens with different elements to determine their mechanical properties. They found that experimental results closely aligned with those obtained through numerical analysis, with an absolute error of less than 5 %. They highlighted the influence of the manufacturing process on final results, emphasizing the importance of pressure control during manufacturing. However, computational numerical analysis does not encompass certain real parameters, such as moisture and flammability, necessitating validation of results through experimental tests or literature information to enhance knowledge and explore potential applications across industries, including aerospace, while considering ecological aspects.

Gadekar & Patel (2022) conducted a study on the design of underground tanks using CAD software. They considered a rectangular geometry suitable for storing liquids like water, oil, or chemicals, ensuring compliance with established regulations. In configuring boundary conditions and software settings, they accounted for lateral soil pressure and liquid pressure. FEM was employed to analyze the tanks' behavior under varying values of the soil's safe bearing capacity. The authors emphasized that previous literature predominantly focuses on elevated tanks, neglecting the impact on underground tanks, and note that software analyses lack detailed modeling or hydraulic loading considerations.

Razo-Carrasco & García-Domínguez (2020) assessed the structural integrity of buildings through in-situ testing and computational numerical analysis. Their methodology enables a comprehensive evaluation of the structural safety of reinforced concrete buildings, whether existing or new, amidst uncertainties regarding their integrity. Conducting tests to determine material mechanical properties is crucial due to varying environmental conditions. However, numerical analysis proves to be an economical and justifiable technique for assessing dynamic load behavior, allowing for the determination of properties such as vibration periods and modes. They stress the importance of result consistency through the comparison of experimental values with program-calculated base reactions.

This work aims to propose a design for the support structure of a rainwater storage tank with a 500-liter capacity, which will be validated through structural analysis using CAD/CAE software. The most important issue addressed is ensuring the structural integrity and stability of the support structure for a rainwater storage tank, therefore, this would be provided a secure and reliable support system for the rainwater storage tank. By proposing a design and subjecting it to structural analysis using CAD/CAE software, the purpose is to systematically evaluate the structural performance of the support structure under various conditions such as load and potential stress points. As hypothesis, for the proposed design for a support structure of a 500-liter rainwater storage tank will demonstrate sufficient structural integrity and stability when validated through structural analysis using CAD/CAE software, ensuring a secure and reliable support system under various load and stress conditions.

Methodology

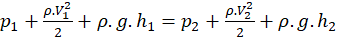

Fluids and mechanics of materials equations

This proposal utilized applied technological research aimed at generating knowledge directly applicable to regions lacking access to potable water. The research adopted an exploratory approach, revealing all process characteristics and executing a simplified version in real-world scenarios. CAD/CAE software facilitated 3D modeling and simulations for designing a support structure for a rainwater storage tank. The simulation outcomes enable analysis of the system's behavior before implementing a rainwater recycling system. To begin, determining the force exerted by water due to its weight is crucial, leading to the application of the Bernoulli equation, commonly used to describe fluid flow in closed systems. The tank's bottom served as the reference level and the maximum volume was treated as a steady flow, aligning with Equation (1) as outlined by Li et al. (2024):

(1)

Where p represents the gauge pressure, ρ stands for the density of water, V denotes the velocity of water flow, g represents gravity, and h signifies the height from the reference level. The principle of equilibrium dictates that an object remains stationary, meaning the forces and moments acting upon it must balance to prevent any changes in motion (Portioli, 2020). Equations (2) and (3) depict the equilibrium conditions, stating that the sum of moments (M) and the sum of forces (P) for static analysis must equal zero:

(2)

(3)

Chethan et al. (2019) define stress as the inherent resistance of all objects to counteract applied forces, whether they involve axial tension or compression, torsion, or flexure. Stress (σ) is related to the load that an element can endure within its cross-sectional area (A), as depicted in equation (4):

(4)

Moreover, validating the design of a structure with the safety factor is crucial, as a higher safety factor implies increased safety for the product or structure. A safety factor of one (1) indicates that the structure or part will fail immediately upon reaching the design load and won't withstand subsequent loads. In cases where the consequences of failure are severe, such as death or personal injury, a higher safety factor is necessary; for metal structures, a maximum value of 1.69 is recommended. As per Nazemosadat et al. (2022), the safety factor (Fs) is determined by the ratio in equation (5) between the yield stress (σy) and the analytically calculated stress:

(5)

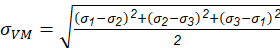

The Von Mises stress is a measure of the distortion energy present in an object and can be determined by considering the principal stresses of the stress tensor at a point within a deformable solid, as illustrated in Figure 1. Shruti et al. (2021) computed this Von Mises stress (σVM) using equation (6):

(6)

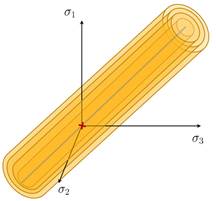

3D Modeling

The design of the structure was based on the geometry and dimensions of a plastic tank available in the market. Figure 2a illustrates the dimensions and arrangement of the structural elements by using SolidWorks 2023 as CAD software. It's worth noting, as suggested by MacDonald et al. (2023), the recommendation to use a square pipe of 50 mm (2 in). Figure 2b depicts the three-dimensional modeling of the structure, highlighting the tank in a different color, as it is an external element whose weight is factored into the structural analysis.

Meshing

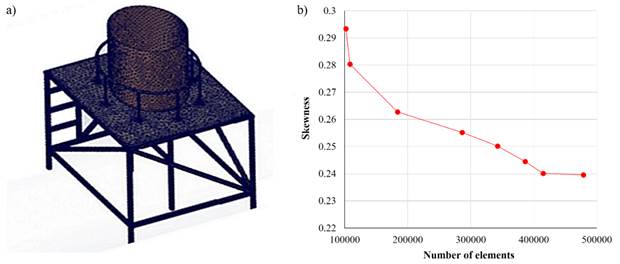

In Figure 3a, the generated mesh for the structure is depicted, applying tetrahedral elements as the primary elements by using Static Structural module in ANSYS 2023 R2 as CAE software. These elements are highly flexible and can be used to mesh complex geometries with irregular shapes. Tetrahedral elements can adapt well to intricate designs, making them suitable for a wide range of applications in engineering and design. Mesh validation was performed through convergence analysis, illustrated in Figure 3b. To achieve excellent physical discretization and results closer to reality, Simbaña et al. (2024) recommend a skewness metric of less than 0.25. Despite employing various mesh generation optimization techniques, the minimum skewness value attained was 0.2395, resulting in 478 723 elements with 718 085 nodes, necessitating substantial computational resources for simulation. Consequently, the previous point, where an average skewness of 0.2401 was achieved, was analyzed, leading to a reduction in elements by approximately 14 %. Consequently, the mesh of the 3D model utilized in the study comprised 414 651 elements and 601 334 nodes.

Results

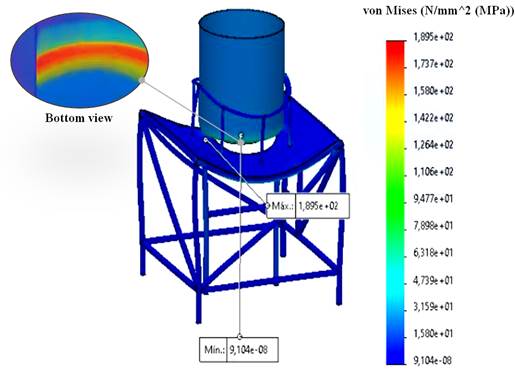

Fixed supports were defined at the points of contact between the structure and the ground, and all contact elements were set with welded conditions. A distributed load of 5.4 kN, generated by the weight of the water and the tank, was applied across the shared area between the storage tank and the structure. Figure 4 illustrates the results of the Von Mises stress analysis in the tank support structure, revealing a maximum value of 189.5 MPa. It is noteworthy that the structural steel has a yield strength limit of 210 MPa and a maximum tensile stress above 400 MPa. Consequently, while the structural elements are subjected to significant stress, they do not undergo permanent deformations as this value remains below the yield limit. The Von Mises stress primarily concentrates on the areas of contact between the tank and the structure, posing no issues in the design and selection of sections for the structural components. It is important to note that the computer's technical specifications were not fully utilized, despite its significant capabilities. The computer has a 12-core processor, but only 4 cores were configured for the simulations, which took approximately 30 minutes.

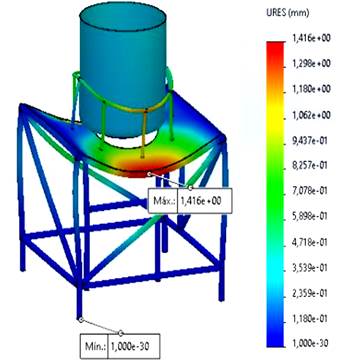

Figure 5 illustrates the simulation of the deformation caused in the tank structure by the weight of a 500-liter volume of water. The force resulting from this volume was calculated as 5.4 kN, and with the modulus of elasticity of 210 GPa for structural steel, it led to a maximum deformation of 1.41 mm. This displacement is considered as deflection at the front edge of the upper surface of the structure. However, upon examination of the color scale, it is noted that the vertical supports serving as structural elements do not exceed 0.83 mm.

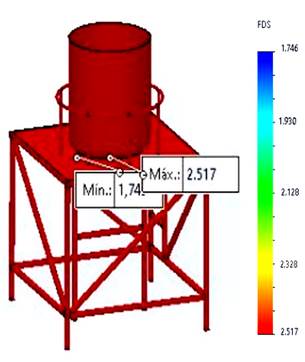

Figure 6 illustrates the safety factor in the simulation of the structure under the established conditions. This factor indicates the structure's capacity to withstand loads without failing, meaning without experiencing permanent deformation or rupture, by comparing it to the expected loads it is designed to bear. It's noteworthy that a square pipe of 50 mm (2 in) made of structural steel was utilized. The minimum value obtained for the safety factor was 1.746, signifying that the structure's load-carrying capacity is approximately 1.75 times greater than the applied load.

Discussion

Verma et al. (2024) conducted a study focusing on designing a structure for a tank, with stress levels anticipated to range between 160 to 200 MPa. Recognizing the criticality of ensuring structural integrity in such designs, a comprehensive literature review was undertaken to validate the obtained stress values. This meticulous validation process yielded a maximum stress projection of 289.5 MPa, which notably falls within the established range observed in other relevant studies. This alignment with existing literature not only corroborates the accuracy of the stress estimations but also underscores the credibility and reliability of the proposed design. Moreover, drawing from the insights provided by Nazemosadat et al. (2022), it was established that the recommended safety factor for support structures should ideally be 1.69, offering a reasonable margin of safety while allowing for flexibility to adjust based on varying risk exposures. For the proposed design, the minimum safety factor calculated was determined to be 1.746, with an absolute error of merely 3.3% when compared to the recommended values derived from the literature review. This negligible deviation from the established safety factor further validates the robustness and adequacy of the proposed design in meeting safety requirements. By meticulously cross-referencing obtained stress values with existing literature and ensuring adherence to recommended safety factors, the study exemplifies a diligent approach to structural design. The findings not only lend credibility to the proposed design but also reinforce the importance of rigorous validation processes in ensuring the reliability and safety of engineering structures.

Despite the advancements in CAD/CAE software, which have remarkably enhanced their ability to simulate real-world phenomena with increased accuracy, many research endeavors still integrate experimental components to complement computational analyses. This combined approach offers a more comprehensive understanding of complex mechanical behaviors and structural responses. For instance, Bai et al. (2020) conducted a study delving into the mechanical properties of structural components subjected to various stress conditions. By conducting experiments, they were able to directly observe and measure physical responses, providing valuable empirical data to validate and enhance computational models. Furthermore, as underscored by Arroba-Arroba et al. (2021), a notable convergence exists between experimental results and those derived from simulations, with disparities typically falling below an absolute error threshold of 5%. This close alignment highlights the efficacy of computational simulations in capturing and predicting real-world behaviors, albeit with a margin of error that is deemed acceptable in engineering practice.

However, it's imperative to recognize that computational numerical analysis is not without limitations. To ensure the validity and reliability of simulation results, it is crucial to adhere to a systematic methodology encompassing well-defined experimental conditions, meticulous calibration of simulation parameters, and the utilization of appropriate simulation techniques. By rigorously defining these factors, researchers can minimize uncertainties and errors inherent in computational modeling, thereby enhancing the credibility of their findings. In essence, the integration of experimental validation alongside computational simulations represents a pragmatic approach to engineering research. By leveraging the strengths of both approaches and mitigating their respective limitations, researchers can achieve a more robust and holistic understanding of structural behaviors, thereby contributing to the advancement of engineering knowledge and practice.

The analysis confirmed that the support structure could withstand the weight of a filled tank, calculated to be 5.4 kN. The structure, composed of a square-section structural steel pipe with a 50 mm diameter, exhibited a Von Mises stress of 189.5 MPa, well below the yield limit for structural steel. The maximum deformation observed was 1.41 mm, with most structural elements remaining below 0.83 mm. The safety factor was determined to be 1.746, exceeding the recommended value by 3.3%. These results validate that the design, with its specified dimensions, selected material, and 500-liter capacity, provides a secure and reliable support system for the rainwater storage tank, confirming the original hypothesis.

Conclusions

A prototype support structure for a rainwater storage tank underwent computational numerical analysis. The practice of collecting, storing, and utilizing a renewable resource like rainwater in everyday activities is crucial for reducing the consumption of potable water, underscoring the need for a well-designed collection system. A structure is needed to withstand the weight of the tank when filled with water, therefore, performing computational numerical analysis contributed ensure that the support structure is designed to resist various loads, including the weight of the tank and the rainwater volume. This analysis provided assurance regarding the structural integrity and safety of the support system CAD/CAE software facilitated 3D modeling of the structure and subsequent physical discretization, resulting in a mesh comprising 414 651 elements and 601 334 nodes of exceptional quality, with a skewness metric of 0.2401. The design accounted for a maximum water volume of 500 liters, resulting in a weight of 5.4 kN. A square-section structural steel pipe, 50 mm (2 in) in diameter, was chosen. Structural analysis through simulations revealed a Von Mises stress of 189.5 MPa, below the yield limit for structural steel. The maximum deformation was 1.41 mm, with structural elements remaining below 0.83 mm. The safety factor obtained was 1.746, surpassing the recommended value for support structures by 3.3 %. Thus, it is confirmed that the design, with its specified dimensions, selected material, and a capacity of 500 liters of water, is suitable for supporting the rainwater storage tank.