INTRODUCTION

Minning is an economic activity that has been growing since the beginning of the 20th century. From 1920 to 2018 the rate of exploitation of each mineral has varied from 1.48% to 7.3% measured in megatons (Mt) [1]. Since the end of the 1990s, mineral exploitation has advanced at a much higher rate than in previous years, which has caused an accelerated depletion of mineral resources [2]. Among the largest industries that make use of the exploited minerals, metallurgy, oil and cement can be named. The cement industry complies with providing the main material for construction, which is cement and which has been key to the process of human civilization [3].

For the cement grinding process, two machines can be used, which are: a ball mill or a VRM vertical roller mill. The ball mill makes use of grinding bodies and they have been the main tool for more than 100 years, although they have a low efficiency, while the vertical mills are much more modern tools that are capable of saving between 45 to 70% of the power consumed [4].

It is important to know that the cement classification process in a VRM can be carried out by air sweep or by overflow the use of the overflow model suggests more energy savings than the sweep model, however it is useless in certain conditions operation (VRM motor at full load or rater load pressure) such as particle size, moisture or hardness [5]. This directly influences energy consumption and the characteristics and quality of the cement.

Some methods to improve the grinding process vary one parameter at a time such as the loading force, the rate of revolution or the fractional filling [6]. Some studies also try to predict energy consumption taking into account the characteristics of the material to be ground in the VRM [7]. An energy and exergy analysis are used to compare the ball mill and the VRM, finding that the VRM is more efficient and consumes less energy, maintaining the quality parameters of the product, so its use is recommended [8]. The grinding performance has been improved by increasing the grinding surface, in addition, it has been compared with other processes such as jaw crushing and the ball mill, finding the VRM with better characteristics in product quality and energy efficiency [9]. A model of material failure can provide different energy levels, which can help improve energy efficiency [10]. With the above, it is observed that no research makes use of optimization methods to find adequate operating parameters in vertical mills.

Crushing processes consume about 3 to 4% of the electricity generated worldwide and about 70% of the energy required in an industry dedicated to mineral processing [11]. That is why it is important to optimize the cement grinding process, in order to obtain better efficiency with the lowest consumption of electrical energy, in addition, it is necessary to take into account certain operating parameters to guarantee a quality product.

Most of the works related to energy consumption vary a single parameter at a time, propose models, make comparisons between grinding processes or perform various energy analyses. The present work takes into account five important parameters in the operation of any VRM such as the load pressure, humidity, the speed of rotation of the motor, outlet temperature and pressure roller [12].

This document is structured by: section one presents the introduction, in the second section is presented the related work, the third section explains the milling process in vertical mills, the methodology used is explained in the fourth section, while in the fifth section all the results obtained are presented and finally, in the last section, the conclusions that were obtained.

RELATED WORKS

The search for optimal operating parameters in vertical milling processes is essential to guarantee a product under all quality standards and that unplanned shutdowns are considerably reduced. However, the complexities of the models or the handling of proprietary software make this task difficult.

There are several optimizations works related to vertical roller mills. The one proposed by [13] proposes the design of the lower rocker arm body that supports the roller and take as optimization objective function the mass of the rocker arm and as constraint conditions the stresses and displacements generated by the roller in the rocker arm in order to decrease the mass while conserving the resistance and deformation. In this way, the design is optimized and the cost is reduced by saving material.

A VRM in its normal operation undergoes cyclic bending stresses due to the roller load which can cause fractures in the mill table so [14] makes use of artificial neural networks to solve the multi-objective optimization problem by determining the maximum and minimum stresses to which the vertical mill can be subjected.

High vibration in a VRM can considerably reduce productivity, using the 7 quality tools and together with a vibrational analysis, an optimization model is obtained that achieves improved productivity and reduced downtime [15].

To predict the vibrations in the upper case of the VRM, use can be made of the fruit fly optimization algorithm (FOA). It shows better precision in simulations. As a result, a vibration pattern can be predicted which will help to understand the state of the VRM and take new safety precautions [16].

Another way to optimize the load and the quality of the cement is by using expert PID controllers, increasing the production of the cement in vertical roller mills [17].

Although there are already some optimization works in the field of VRMs, there are still few or almost none those works that aim to optimize key parameters in the operation in order to reduce electricity consumption.

GRINDING PROCESS IN VERTICAL ROLLER MILLS (VRM)

A vertical roller mill is suitable equipment for grinding and drying wet materials, which can be carried out in the same equipment [18]. Some of the materials that can be processed in a VRM are:

1) Clinker for cement manufacturing

2) Raw materials for cement manufacturing

3) Pozzolan

4) Metal dross

The grinding process in a VRM is carried out by placing a certain amount of material on a horizontal surface that is in motion, at a pressure sufficient to fracture the materials on the bed. The bed materials are considerably smaller, so it is necessary to form a stable grinding bed between the rollers and the grinding table to withstand the pressure without the material being ejected from the grinding pressure zone. [19].

A vertical roller mill can be divided into 3 sections.

1) Motor and gears

2) Grinding

3) Drying and separation.

In the grinding process, the material is fed to the grinding table and due to its speed, the material is directed towards the rollers where it is milled. This process is one of the most efficient in the cement industry [15].

The drying process consists of a stream of recirculated gases, which can come from the clinker kiln or from hot gas generators. Drying usually occurs on the mill table and in the vertical sections towards the separator [20].

Finally, the pressure exerted by the rollers on the table causes the material to rise towards the separator which together with fixed plates and the cage separates the material to the desired size. The rejected coarse material is recirculated back to the mill [20].

In Fig. 1, shows a vertical roller mill in which the three sections mentioned above can be easily distinguished. The motor, grinding table, rollers and separator are clearly visible. The material and hot gas inlet ducts and the material outlet can also be seen.

METHODOLOGY

Mathematical Model

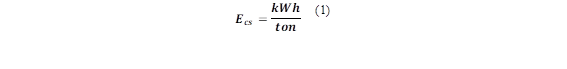

In grinding processes, it is common to use the specific energy [21]as observed in (1).

The ratio between the kilowatt hour, which is the unit of measurement for accounting for electricity consumption, and the kilogram, which is the unit of measurement for mass, is also known as energy efficiency and is widely used in the field of mineral processing. This allows the performance of the grinding process to be evaluated as well.

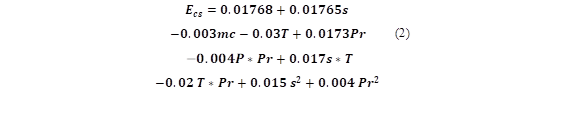

In vertical roller mills there are several factors that influence the performance of the grinding process [22] which are moisture content (mc), grinding table rotation speed (s), load pressure (P), outlet temperature (T) and the pressure rollers (Pr).

The specific energy model [23] can be seen in (2). The resulting model is non-linear, so some variables, such as roller pressure and speed, are of degree two and other variables can be multiplied by others. There is only one independent term.

The model was developed using the Box-Behnken method, using historical data on the energy consumption of the VRM and the number of tons of cement produced.

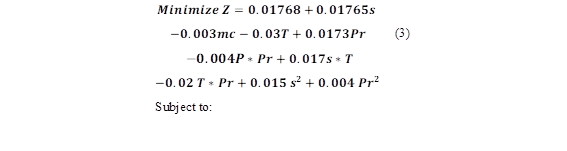

Taking into account the above, the formulation of the optimization problem is as follows:

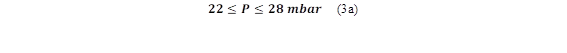

The restriction data are obtained using a Pffeifer vertical roller mill. Parameter intervals documented in articles, manuals and INEN standards were taken into account. To guarantee a desired fineness of less than 45 microns in the case of cement, a charge pressure between 22 and 28 mbar [24] as observed in restriction (3a), a pressure of the rollers between 100 and 190 mbar [24] defined in the restriction (3e), speed between 886 and 1198 rpm [25] as indicated in the restriction (3b) the moisture content between 0 and 3% [26] as observed in restriction (3c), and the outlet temperature between 0 and 97 ˚C [26] be used as indicated in the restriction (3d).

Model Optimization

The objective function of the proposed model clearly presents non-linear terms, so it must be solved using non-linear programming methods. To choose the appropriate method it is necessary to check certain characteristics of the objective function.

As a first step it is necessary to check the convexity or concavity of the function. For this it is necessary to obtain the gradient (4) and Hessian of the objective function (5).

From the Hessian matrix, its eigenvalues (6) are obtained, which are equal to or greater than zero, so it is a positive semi-definite matrix.

Taking into account the considerations that the gradient is greater than zero and the Hessian matrix is positive semidefinite, the objective function presents convexity.

With this in mind, we proceed to solve the optimization problem proposed in (3). In this case, in addition to the Python programming language, nonlinear programming solvers from the Pyomo and Scipy packages are uses. Both solvers are used to ensure the accuracy and speed of convergence of the model and to select the model that yields parameter values that meet the constraints of the optimization problem.

The Pyomo package uses the ipopt solver [27] to solve nonlinear programming problems. Table 1 shows the optimal values for each variable and the objective function.

Table 1: Optimized values obtained using Pyomo

| Variables | Optimized Value |

|---|---|

| P | 28 |

| s | 886 |

| mc | 3 |

| T | 0 |

| Pr | 100 |

| Z | 11.82 |

Finally, the Scipy package makes use of sequential least-squares programming [28], which is a widely used solver for non-linear programming problems. In Table 2, you can see the optimized values using Scipy.

DISCUSSION

The benefits of optimizing any process or model are many, such as better tuning the parameters of a particular controller or reducing associated costs by making it more efficient. The grinding process optimized in this work is important because it provides the optimum operating parameters. Optimized parameters avoid potential damage to machine components, such as preventing VRM rolls from breaking due to out-of-range operating parameters or high energy consumption with low production.

Grinding in the cement industry is a critical process as it is the last step before the finished product is obtained. There are other sub-processes involved in grinding, such as material transport or separation, but this work focuses on the actual grinding process that takes place within the VRM.

In Ecuador, there are several companies dedicated to the production of cement. In the center of the country there is a well-known cement industry from which the energy consumption data for the grinding process could be obtained. For reasons of confidentiality, the name of the company is withheld.

The company's grinding process consists of a VRM, which will replace a ball mill previously used for cement production in 2021. The current VRM has a capacity of 100 tons per hour. This process also includes the raw material feeding sub-process, which is carried out by means of dosing tables, the finished product separation sub-process and transport to the finished product silo. The company also has two other VRMs, one for the production of raw meal, which is heated to 1200 ˚C to produce clinker, the main ingredient of cement, and the other for the production of Petcoke powder, the main fuel for the clinker kiln.

Taking this into account, the average consumption data obtained is 78,408.5 kWh per day. Similarly, the average cement production is 2228 tons. Dividing the consumption value by the number of tons produced gives a value of 34.39 kWh/tons, which means that it takes 34.39 kWh to produce one tons of cement. The Ecs value obtained takes into account all the processes involved, such as raw material dosing, separation of the final product and transport. However, if only the VRM grinding process, which accounts for 40%, is specifically analyzed, the value obtained is 13.75 kWh/tons.

The packages used to optimize the problem proposed in this work provide very similar data. The Pyomo package provides optimized values of the operating values within the given constraints, but Scipy packages provide optimized values very close to the constraints, which, by applying rounding methods, are equal to the values provided by Pyomo. Taking this into account, for further comparisons with the production data presented above, the values optimized by the Pyomo package will be used, which are considered to be the most accurate and reliable values for this work.

The value of the objective function after the optimization process is 11.82 kWh/tons, while that of the normal process without optimization of the operating parameters is 13.75 kWh/tons. This reduction corresponds to 14.03% of the energy consumption of the grinding process carried out by the VRM. To achieve this, it is necessary to change the values of the current mill parameters to the optimized values, which are: for a feed pressure of 28 mbar, the table speed should be set to 886 rpm, the moisture content of the material should be 0% the outlet temperature should be 0 and the pressure roller should be 100 bar. This ensures low energy consumption and a minimum cement production of over 2200 tons per day. Table 4 summarizes the results obtained.

Table 4: Comparison of the results obtained

| Variable | Ecs (kWh/ton) |

|---|---|

| Actual | 13.75 |

| Optimized | 11.82 |

| Difference | 1.93 |

It is important to know the savings in dollars of the consumption of the milling process. Currently, in the year 2023, the cost per KWh in Ecuador is $0.105 for voltages between 351V and 500V [29]. Considering this, before the optimization process, the consumption was $3216 for a production of 2228 tonnes of cement per day, and with the optimized parameters, the consumption is $2686 for the same production of cement. This represents a saving of $530 per day.

Effect of the parameters in Ecs

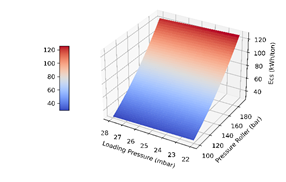

When comparing the loading pressure P with the pressure roller Pr, the specific energy Ecs increases if the loading pressure and pressure roller also increases due to the features of the raw material. Due to this increase in ECS, it is necessary to carry out optimal quality control of the raw material used in the cement manufacturing process. By increasing the loading pressure and the pressure roller to their maximum levels, the maximum Ecs can be obtained as shown in Fig 2.

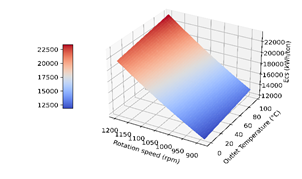

Another scenario can be given by comparing the rotational speed with the outlet temperature as shown in Fig. 3. If both parameters are increased, a higher energy consumption of the mill is evident.

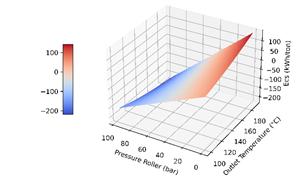

In Fig 4, the comparison between pressure roller and outlet temperature can be observed. In this scenario it can be seen that pressure roller has almost no effect on Ecs in contrast to the outlet temperature, which does.

Taking into account the above, it can be taken into consideration that the pressure roller, outlet temperature and rotation speed parameters has a large effect on Ecs.

CONCLUSIONS

In a VRM vertical roller mill, charge pressure (P), table speed (s), moisture content (mc), outlet temperature (T) and pressure roller (Pr) are parameters that directly affect grinding efficiency and energy consumption. In the mining industry, specific energy is a metric that can be used to determine the energy consumption per tons of material produced.

According to several studies, it is known that any crushing or grinding process represents 30% or 40% of the energy consumed in any industrial process that integrates these techniques. Using the mathematical model of a VRM, the optimization problem was posed with the objective function being the mathematical model itself and the constraints being the operating intervals of the parameters described above.

Three optimization packages, each with a different solver, are used to solve the optimization problem. Although the three packages give similar results, the results of the Pyomo package are chosen because it gives optimized data within the constraints, unlike the other packages which give very approximate results.

The value of the optimized objective function is 11.82 kWh/tons. The data obtained from a well-known cement company in central Ecuador has a specific Ecs of 13.75 kWh/tons. Comparing both results, it can be concluded that the optimized value is equivalent to 14.01% less energy consumption, guaranteeing a minimum production of 2200 tons of cement. There is a saving of $530 between the optimized model and the non-optimized model.

These results sufficiently validate the proposed model. Reducing the energy consumption by guaranteeing the minimum cement production can bring several benefits, such as saving money or having a more stable control and production of cement production.

The model proposed in this work is specific and cannot be generalized. It is recommended to develop models that can be generalized to VRMs and perform multi-objective optimizations to reduce energy consumption and increase production.