Introduction

Composite materials are currently the lightest construction material available and represent the best alternative for creating lightweight spatial structures with a visually minimalist appearance (Milosevic et al., 2013). These materials consist of threads in the longitudinal/warp direction and in the transverse/weft direction, forming a bidirectional orthogonal mesh that intertwines in two mutually perpendicular directions (0° and 90°) (São João et al., 2016). The threads that make up the fabric are composed of several twisted filaments, forming a yarn. The arrangement of these yarns determines whether the weave is single or double, and it can also be open or closed, depending on the spaces between the threads when forming the mesh (Carranza & Taco, 2011). The materials used to manufacture these high-strength threads (Corazza, 2006) include polyamide, polyester (PES), fiberglass, and aramid (Santomauro, 2008), additionally, polytetrafluoroethylene (PTFE) is also found (American Society of Civil Engineers, 2017).

The fabrics are coated with layers of polyvinyl chloride (PVC), PTFE, polyolefins, and silicone (American Society of Civil Engineers, 2017). To enhance the durability and self-cleaning properties of polymeric materials, top layers of acrylic, polyvinylidene fluoride (PVDF), and polyvinyl fluoride (PVF) are used (Zhang et al., 2012). The combination of innovative polymeric coatings with high-strength synthetic fibres forms a material with structural functions (Antona, 2015). This material exhibits properties such as high mechanical strength, hydrophobicity, fire and solar radiation protection, climate regulation, lower maintenance costs, ease of installation and dismantling, ability to support loads and its own weight, as well as resistance to tearing and fungal proliferation (Hadvani & Patel, 2022a; Monjo-Carrió & Tejera, 2011). It efficiently meets the requirements for covering large areas due to its lightness and cost-effectiveness compared to other structural systems like concrete shells (Cerdá, 2019).

The mechanical behaviour of composite fabrics depends on the type of fibres, thread diameter, fabric geometry, weave, and spacing (Beccarelli, 2015; Schlaich et al., 1990; Tolani et al., 2016; Zhang et al., 2012), as well as the processes they have undergone, the coating material, mechanical treatments received, moisture content, fibre density per unit volume, and temperature (Tolani et al., 2016). The coating is bonded to the fabric fibres at high temperatures through a chemical and mechanical bond, directly influencing the shear stiffness of the assembly (Schlaich et al., 1990). The fundamental property of these materials is their nearly inextensibility (Aguirregabiria, 2019). They exhibit complex, nonlinear, hysteresis, and anisotropic behaviour (Bridgens et al., 2004), capable of bearing loads primarily in tension (Berger, 1999; Hadvani & Patel, 2022b; Kamal, 2020). By definition, a structure made of composite fabrics, like membranes, develops forces only within its plane, with minimal or no bending moments, eliminating compressive forces. If both tension and compression are possible, they are referred to as membranes (Schlaich et al., 1990).

Due to their small thickness, tensile structures cannot withstand pressure; therefore, they are stabilized through pre-stress forces in tension (Valdés et al., 2009). These structures experience initial tensions and even after undergoing additional service loads, they manage to maintain their stability (Schlaich et al., 1990). It is important to mention that this is done in both directions because when the warp tension is less than the weft tension, the negative tension in the warp direction can reduce the material efficiency (Zhang et al., 2012). Generally, membranes with higher tensile capacity are more prone to tearing, which is directly related to the strength per unit width, yarn density, and the duration of loads (Cerdá, 2019). The safety factor for tensile structures is higher than for traditional structures due to the lack of reliability in the production process of composite materials, the assembly of the structure, and its connections; typically, it ranges from 4 to 7 (Gosling et al., 2013). Designers must consider local conditions such as climate, wind exposure, snow, and other environmental factors that can influence the design and behaviour of the structure (British Standards Institution, 2023).

Among the main characteristics of composite fabrics in architectural applications is the direct relationship between tension and form (Rivas, 2018). The shape of a tensile structure becomes the most important feature both architecturally and structurally (Milosevic et al., 2013). Textiles optimize structure behaviour due to their lightweight and flexibility (Mubashra et al., 2021), incorporating new geometric possibilities. Architecture has utilized textiles for millennia, being one of the earliest forms of construction produced regularly and widely recognized since the primary act of erecting a tent (Knippers et al., 2011). However, today it represents one of the most advanced and innovative construction methods, continuing to evolve and capable of adapting to permanent structures with lifespans similar to buildings constructed with much heavier materials (Textile Institute, 2015). Regardless of the structural system, tensioned textiles in architecture exhibit pronounced formal characteristics that distinguish them from other construction systems (Ambroziak & Kłosowski, 2017; Lin & Roithmayr, 2015). There is a notable growing interest in these materials within the architectural field due to their performance capabilities and complex forms (Blonder et al., 2019), achievable through recent technologies and significant advancements in regulation and construction coding (Bedon, 2016).

Permanent tensile structures entered the construction industry with exceptionally large spans, drastically changing the way permanent buildings are conceptualized (Kamal, 2020), serving both as structure and cladding (Bridgens et al., 2004). One example is the Denver International Airport (USA), completed in 1994. This project established itself as a public structure enclosed with a fabric roof, highlighting the characteristics and potential of tensile structures at that time. Compared to other roofing construction systems, it demonstrated efficiency by requiring less construction time, providing protection during interior space construction, and having a weight that is only a tenth of traditional systems. This not only reduces the cost of support elements and foundations but also decreases the use of mechanical equipment and drainage systems (Berger, 1999), resulting in cost reductions between 50% to 60% (Tolani et al., 2016). Similarly, the London 2012 Olympic Stadium, with its retractable roof, used less than half of the steel required by comparable stadiums, significantly reducing environmental impact and becoming one of the lightest Olympic stadiums constructed. This innovative design not only lowered construction costs but also minimized electricity consumption due to its translucent nature, thereby improving the building's energy efficiency (Lin & Roithmayr, 2015). Therefore, these large span tensile structures are more efficient for roofing systems due to their lightweight, translucent, and flexible nature, enabling a wide range of dynamic shapes. They are also cost-effective due to reduced steel usage, quicker construction times, minimized energy consumption, and minimal maintenance (Bridgens et al., 2004; Hadvani & Patel, 2022a; Tolani et al., 2016).

There is discussion about systems capable of covering large spans (Bridgens et al., 2004; Hadvani & Patel, 2022a; Ivanova, 2022; Kamal, 2020; Lin & Roithmayr, 2015), which allow for open spaces without the need for intermediate supports, less material usage, and generate lower stresses in supporting structures. These systems are applied in buildings with complex volumetric and spatial solutions, most frequently in roofs (Hadvani & Patel, 2022a), combining tensile steel elements to create unique and effective solutions for public, industrial, and agricultural structures (Ivanova, 2022). Composite fabrics, together with the supporting structure, can achieve distances ranging from 3 to 20 meters up to spans of 200 meters (Kamal, 2020), with very lightweight materials that are minimally affected by ground acceleration during seismic movements (Tolani et al., 2016).

Currently, there are several technologies developed to enhance membrane performance, ensuring exceptional strength, dimensional stability, and lightweight materials (Serge Ferrari, 2023). This approach results in more stable composites by significantly reducing disparities between warp and weft, achieving consistent and balanced stiffness throughout the fabric (Forster & Mollaert, 2004). Deformation under load is minimized, which helps extend the material's lifespan (Zhang et al., 2012).

In this context, the present study provides a comprehensive overview of the applications of permanent tensile structures made of composite fabrics in Ecuador. It explores the types of applications in terms of usage and regional implementation. A descriptive analysis of the technical, mechanical, and physical properties is provided to understand their characteristics as structural elements. Ultimately, the aim is to contribute significantly to the understanding of knowledge and technological advancement in the field of tensile roof structures within the Ecuadorian context.

Method

This exploratory-descriptive study employs a mixed-methods approach, focusing exclusively on tensioned structures made of composite fabrics implemented by specialized companies in Ecuador. The study focuses on projects that have undergone a design process for the shape and dimensioning of the supporting structure, under parameters of structural stability and considering the seismic conditions of the country.

In the initial stage, an exploration of specialized companies in the country was conducted using the Google search engine. Once identified, the companies were contacted for selective interviews to form the sample. Tolani et al. (2016) mention that the design of tensile systems is based on the properties of the material and its behaviour under loads, requiring the participation of specialists for form-finding, static analysis, and dynamic analysis. In this context, the collection of information and selection parameters focused on the following variables: the existence of a formal architectural and seismically resistant structural design process carried out by an interdisciplinary team, as well as a database of completed projects and technical catalogues of the materials used.

Next, a typological classification was conducted according to the characteristics of the application:

In this phase of the analysis, it was established that the projects must be classified exclusively within a specific category. Table 1 shows the classification of the 8 typologies, identified with the letters 'a' to 'h'. Each type includes a descriptor based on application characteristics, allowing differentiation between industrial covers, sports cover, educational covers, educational/sports covers, plaza and park covers, façade applications, shade elements, and acoustic shells. Additionally, each project was categorized according to its geographical location: coastal, highland, Amazon, and insular regions.

Based on the catalogues provided by the manufacturers of composite fabrics used in the projects, the technical characterization was carried out under the following parameters: physical properties such as weight, thickness, and dimensional stability; mechanical properties such as tensile strength, tear resistance, and adhesion; and optical and solar properties such as visible light reflectance, visible light transmission, ultraviolet transmission, and solar reflectance index.

The values collected from the catalogues were systematically recorded in a data collection matrix. Subsequently, the mean of these values was calculated, allowing for a representative synthesis of the analysed properties.

Results and discussion

3.1 Project by region

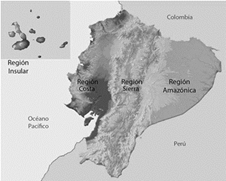

A total of 107 projects were recorded in Ecuador, distributed across different regions of the country. Of these projects, 42,5% are located in the highland region, 37,9% in the coastal region, 18,4% in the Amazon region, and 1.1% in the insular region (Figure 1).

It is notable that approximately half of the projects are located in the highland region, characterized by temperatures ranging from 15°C to 24°C. This is followed by the coastal region, where temperatures range from 22°C to 31°C. In the Amazon region, recorded temperatures are from 22°C to 28°C, while in the insular region, temperatures range from 21°C to 32°C.

The geographical diversity of Ecuador, evidenced by its varied climatic conditions, highlights the versatility of composite fabrics across all its regions. These materials, sourced from different manufacturers, are used as structural elements and meet international quality standards. According to the technical specifications established in the catalogue of the company Estructuras Tensadas de Ecuador, the membranes can be used in environments with temperatures ranging from -30°C to 70°C, in compliance with the international standard DIN EN 1876:2 of the German Institute for Standardization, which describes the method and parameters for determining the temperature properties of coated fabrics (Estructuras Tensadas, 2024).

3.2 Project by application type and average construction area

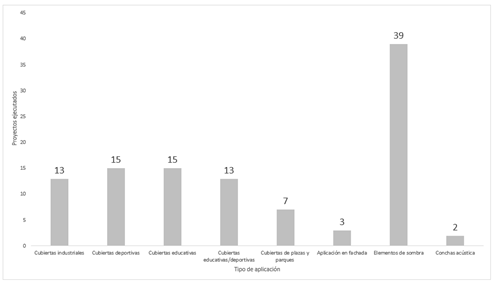

The systematic and typological classification has allowed the identification of the main applications of membranes in tensile structure projects in Ecuador (Figure 2). There are 39 projects notably focused on shade elements, with an average coverage area of 399 m². These structures are primarily constructed in dining spaces, parking lots, corridors, public transport stops, terraces, bleachers, and as urban furniture.

In the category of covers in educational centres, 15 projects have been identified, implemented in shaded and resting areas, with an average area of 325 m². Additionally, there were 15 applications in sports covers, covering an average of 791 m², encompassing all types of sports courts, including pools. The category of educational/sports covers, corresponding to 13 projects, exclusively includes installations in public and private educational centres, with an average area of 469 m².

Thirteen industrial covers were identified, specifically installed in production and distribution lines of various products, meeting temperature, light, and height requirements, with an average area of 1490 m². Additionally, seven covers for squares and parks were found, with an average area of 1970 m².

In the category of facade applications, three projects were recorded, with coverage areas of 155 m². Finally, in the category of acoustic shells, two projects were counted, primarily constructed in the public sector, with an average area of 313 m².

The typological analysis shows that the main application of permanent tensile membrane structures is in the category of shade elements. This is followed by covers applied in educational contexts, sports cover, and educational/sports covers. Next in line are industrial covers, covers for squares and parks, façade applications, and acoustic shells. The significant presence of shade elements using composite fabric tensile systems reflects the introduction of new applications in this context, as the most internationally recognized application is in stadiums (Tolani et al., 2016), specifically in sports areas. From a construction perspective, there is a notable hierarchy based on the average application area. Covers in squares and parks lead in terms of extension, followed by industrial covers, sports cover, educational/sports covers, educational covers, shade elements, and acoustic shells. Interestingly, façade applications show a lower average application area for composite fabric tensile structures.

Source: Tenzo, (2024).

Figure 3: Permanent tensile membrane structures in Ecuador a) Industrial roof. b) Sports roof. c) Education roof. d) Educational/sports roof. e) Plaza roof. f) Facade application. g) Shading elements. h) Acoustic shell.

Figure 3 shows photographs of projects classified according to the typology of application of composite fabric in tensile structural systems. Image a) illustrates an industrial cover designed for a food warehouse in the coastal region. Image b) corresponds to a sports cover built for the Guayaquil Tennis Club in Samborondón, also in the coastal region. Image c) presents an educational cover installed at Intisana School in Quito, located in the Sierra region. Image d) shows an educational/sports cover located at Martim Cereré School, also in the Sierra region. Image e) represents a cover designed for Plaza Cívica Joya de los Sachas, in the Amazon region. Image f) illustrates the façade of the Lounge at Universidad Espíritu Santo in Samborondón, in the coastal region. Image g) shows shade elements used as urban furniture in Ambato, in the Sierra region. Finally, image h) presents an acoustic shell built for Ágora de Yachay, in the Amazon region.

3.3 Technical, mechanical, and physical properties

The technical properties of the studied composite fabrics correspond to high-tenacity polyester (PES HT) yarn types. The surface types identified in the suppliers' catalogues include PVC, PTFE, PVDF. The weight ranges from 900 g/sqm to 1050 g/sqm, and the thickness of the membranes ranges from 0,72 mm to 1,14 mm.

Regarding the mechanical properties, the main ones provided by the manufacturers are tensile strength, tear resistance, and adhesion. For tensile strength, there are two values presented for warp and weft directions because the fabric is stressed in both directions, each with its own strength. The characteristic values range from 420/400 to 1000/800 daN/5cm. Similarly, tear resistance is represented by two values ranging from 120/110 to 160/140 daN/5cm. The adhesion strength between the layers composing the composite ranges from 11 to 15 daN/5cm.

The physical properties are classified based on dimensional stability, fire behaviour, and optical and solar characteristics. Dimensional stability, characterized by elongation, is less than 1% or 1,2%. All composite fabrics are classified as type B1 according to DIN 4102-1. Visible light reflectance, which refers to the amount of visible light a surface reflects, ranges from 84% to 94%. Visible light transmittance, indicating the amount of light that can pass through a material and be perceived by the human eye, ranges from 5% to 9%. UV transmittance for all composite fabrics is 0%, and the solar reflectance index, which measures a material's ability to reflect incident solar radiation rather than absorb it, ranges from 85% to 95%.

Table 2 concisely presents the characteristic values of the technical, mechanical and physical properties of the membranes used in the projects analysed and classified above. In terms of weight and thickness, a very significant reduction of the dead load of the structure and therefore of the dimensions of the support and foundation system is evidenced. The tensile system based on composite fabrics represents the best option to cover large spans, due to its lightness and flexibility, achieving structural efficiency, less weight and greater coverage area. Cost-effectiveness is achieved due to shorter installation time and lower transportation costs. Composite fabrics require minimal maintenance compared to conventional structural systems such as steel. UV, humidity and temperature variation resistance standards are met, and the material has a manufacturer's warranty averaging 15 years. The mechanical properties exhibit a material with competitive structural performance in the market, as it functions as a coating, it provides immediate coverage after installation, making it a fast construction system, which has a direct impact on the economic field. The thermal performance remains stable over time, the mechanical behaviour presents equal resistance before and after aging (São João et al., 2016).

The physical properties related to dimensional stability and fire behaviour demonstrate characteristics of an outstanding material that competes directly with traditional materials.

The optical and solar properties significantly contribute to the energy efficiency of the project, directly impacting a reduction in electricity consumption. These characteristics, along with a notable adaptability to various formal designs, position tensile membrane structures as a versatile, cost-effective, and environmentally friendly solution.

When addressing the topic of permanent structures, it is crucial to mention the expected lifespan for which the membranes are designed. According to the specifications provided by the manufacturers of the membranes used in the analysed projects, the expected lifespan exceeds 30 years, contingent upon maintenance and the climatic conditions of the installation region.

Finally, Table 2 shows that composite materials have a classification based on their behaviour in fire. However, it should not be interpreted that they must meet the same standards as conventional materials such as steel and concrete, since the decrease in strength over time due to exposure to fire is less applicable. While it is evident that the material must be flammable, it should be fire-resistant for a considerable time for the evacuation of people to the outside, taking special consideration of the smoke and burning droplets that can be generated (Monjo-Carrió and Tejera, 2011).

Conclusions

Tensioned composite fabric systems represent the best alternative for constructing roofs, due to their ability to achieve large spans. Their application is particularly notable for achieving forms that are unattainable with conventional materials, providing designers with the ability to experiment with form.

In the Ecuadorian context, these systems are in an initial phase of adoption, primarily through architectural roof construction projects in the Sierra region. Unlike international projects of significant magnitude, it's important to note the absence of a national regulation establishing structural design parameters and optimal characteristics for composite fabrics to be applied in permanent structural systems.

Although it represents an economically viable option, it's important to note that its application is limited to systems exclusively subjected to tensile stress. In cases where projects need to respond to other types of stresses, other more appropriate construction solutions become necessary.

From the perspective of designing and constructing projects involving tensioned roofs, the importance of an interdisciplinary team in the design and execution process is emphasized. This team typically includes at least one architect, one civil engineer, one mechanical engineer, and one textile engineer.

The most widely used composite fabrics in the field are those made from high-tenacity polyester (PES) yarns coated with PVC. However, all possible variations in composition available in the market are developed with technology that allows them to perform adequately in any climatic condition in Ecuador.

Due to the potential of tensioned composite fabrics for roofs to generate complex geometries, sometimes approaching plasticity, it is crucial to assign careful attention to structural calculations, especially regarding wind load considerations, taking into account the effects of both leeward and windward sides.

Composite fabrics used in roofing systems are designed to allow varying degrees of light transmission into the interior. However, this attribute should not be considered in isolation, as it is directly related to thermal comfort implications. In this regard, the higher the light transmission into the interior, the greater the likelihood of unwanted greenhouse effects occurring. From another perspective, translucency depends on the type of finish the fabric has; for instance, silicone-coated fabrics tend to soil more easily than acrylic-coated ones, with dirt potentially altering the translucency of the space.

Composite fabrics used in roofing systems are designed to allow varying degrees of light transmission into the interior. However, this attribute should not be considered in isolation, as it is directly related to thermal comfort implications. In this regard, the higher the light transmission into the interior, the greater the likelihood of unwanted greenhouse effects occurring. From another perspective, translucency depends on the type of finish the fabric has; for instance, silicone-coated fabrics tend to soil more easily than acrylic-coated ones, with dirt potentially altering the translucency of the space. Composite fabrics contribute to the conception of lightweight structures that combine high-strength membranes with steel support systems, achieving stability through the uniform distribution of loads across the entire surface. These structures are versatile and can adapt to various shapes and sizes, responding to morphological design that aims to stabilize the form with the fewest possible supports. The design process of these structures is based on the "form finding" phase, which integrates criteria from both formal design and structural stability. Starting from the desired form, the fabric patterning is established, the support structure is dimensioned, and load transfer mechanisms are determined. These systems are notably lightweight due to the minimal material required, resulting in a more cost-effective solution compared to more robust systems. By using less steel, they entail lower maintenance costs by preventing corrosion processes and focusing more on maintaining the cleanliness of the tensioned material. Therefore, they are more economical to maintain.