I. INTRODUCTION

Manufacturing companies face various operational challenges, including unpredictable market changes. According to Deeb et al. (1), manufacturing businesses frequently encounter unexpected fluctuations and uncertainties caused by novel regional mandates or rules, emerging technologies and materials, new market niches, and the growing need for additional product attributes. Market fluctuations can present challenges for manufacturing organizations, requiring them to adjust their production methods, effectively managing stocks, and fulfilling client requests. Furthermore, the use of Industry 4.0 technology brings forth both advantageous prospects and obstacles for manufacturing organizations (2). Gholami et al. (3) highlight that while Industry 4.0 can increase efficiency, customizability, and autonomy, small and medium enterprises (SMEs) in the manufacturing sector still face challenges in upgrading their manufacturing systems and adopting these technologies. This can be attributed to factors such as cost of implementation, lack of technical expertise, and resistance to change (4).

Facing these challenges increases the need for companies to improve their flexibility (5) (6), and adaptability has become necessary for survival and success. Flexibility is a key determinant of success in the context of expectations. Consumer preferences are constantly evolving and driven by changes in lifestyle, demographics, and socioeconomic factors. Companies that can adapt their products, services, and customer experiences to align with shifting demands will be more successful in retaining and attracting customers (7). Flexible companies can implement contingency plans, react to and solve problems quickly, diversify their offerings, and mitigate risks effectively (8) (9).

Adeodu et al. (10) state that many manufacturing companies encounter obstacles that prompt them to implement continuous improvement methodologies like Six Sigma (SS), Lean Manufacturing (LM), Lean Six Sigma (LSS), and Lean Sigma (LS). These methodologies empower regional companies to overcome their technological limitations and other shortcomings, enabling them to compete with their more advanced counterparts (11). To improve the processes, these approaches use statistical and lean tools that improve and solve problems, such as the Single Minute Exchange of Die (SMED), a tool used in manufacturing and production processes to reduce the time it takes to perform equipment changeovers or setups. SMED aims to minimize the time required to switch a production line from producing one type of product to another, ideally achieving changeovers in less than ten minutes (12) (13).

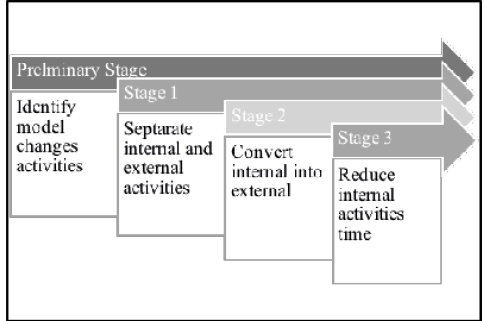

SMED was introduced by Shigeo Shingo, a Japanese industrial engineer and one of the key contributors to the Toyota Production System (TPS). The underlying principle of SMED is to convert as many changeover tasks as possible from internal (activities that must be performed while the equipment is stopped) to external (activities that can be performed while the equipment is running) (14). According to a study by Zhang et al. (11), SMED involves the following key steps:

Separation of internal and external activities

Convert internal tasks to external tasks

Streamlining internal tasks

Standardization

Continuous improvement

By implementing SMED, manufacturers can significantly reduce the downtime between production runs, increase production flexibility, and enhance overall operational efficiency. This approach is particularly beneficial in industries with frequent changes in various products or production runs (15).

In Mexico, it is crucial to use these continuous improvement methods or methodologies because of the country’s ongoing establishment of foreign enterprises. By 2023, the country had 608,484 manufacturing enterprises, with 484 located in Chihuahua and 416 in Ciudad Juarez. These two cities account for almost 80 % of the state’s overall manufacturing industry. These enterprises collectively created a total of 2,976,510 jobs across the country, with 503,759 jobs in Chihuahua and 326,298 jobs in Ciudad Juarez. This accounts for over 60 % of jobs at the state level and 11 % at the national level. Tijuana surpasses Ciudad Juarez and other influential industrial cities in terms of the number of IMMEX enterprises, with a total of 596. Tijuana generated 259,968 jobs, whereas Ciudad Juarez generated 326,298 jobs, making a difference of 66,330 jobs. Despite having fewer enterprises, Ciudad Juarez outperformed Tijuana in terms of job creation. This highlights the significance of conducting such research in the sector to make a beneficial contribution to the economic and social dimensions (16).

Although companies worldwide are currently using SS, LM, and LSS approaches to improve their processes and become more flexible, some issues with these approaches represent disadvantages. For example, Kulkarni et al. (17) applied SS methodology to a company dedicated to manufacturing boring tool holders. Initially, the process had many rejects owing to variations in the two critical dimensions and using the DMAIC cycle (Define, Measure, Analyze, Improve, Control) and tools such as control charts, fishbone analysis, root cause analysis, capability analysis, and control plan. Their application was focused on reducing the defects of the process; once the methodology is implemented, the sigma level of the process increases from 2.49 to 3.51, so the objective of taking the process to six sigmas is not achieved. However, the authors did not mention the analysis of the measurement system as a step in their methodology. In projects involving quality improvement, it is essential to ensure that the measurement system correctly discriminates between acceptable and nonconforming parts. Finally, this application required 240 days to achieve the results, so it can be concluded that the current approaches can take up to a year to provide company results. Given the current situation in the supply chain, it is not feasible for companies to wait a long time to see improvements in the process.

In another study, Guleria et al. (2) implemented Lean Six Sigma in an automotive company dedicated to axle manufacturing. Initially, the company had many rejects owing to problems with the components that make up the rear axle. The company decided to implement the LSS approach to find waste in the defect reduction process. The tools used during the implementation of the methodology are the Value Stream Map (VSM) and 5S, with which it is possible to reduce the material handling inside the building and the use of layout because of a better organization. Thus, the percentage of defects was reduced from 10.4 % to 3.20 %, the sigma level of the process was increased from 3.34 to 3.94, and the Lead Time was reduced from 12 to 11 days. In this implementation, it can be observed that the sigma level does not reach the six-sigma level, which is the philosophy of the SS approach. However, the author does not mention the analysis of the measurement system to ensure that it correctly discriminates between the good and bad parts. Finally, it is essential to note that the implementation of LSS, as performed by these authors, takes 240 days, which is too long for the company in terms of cost and waste.

Nallusamy et al. (18) use an approach based on Lean Manufacturing, in which they use different Lean tools to improve productivity in an automotive production process. Among the tools used are: SMED and Kaizen. Implementing this LM approach reduces the cycle time from 170 to 140 minutes and Lead Time from 6.9 to 3.6 days. During this implementation, an analysis of the Measurement System is not included to see the impact it has on the measurement of the variables used to measure the improvement; on the other hand, the implementation time of this approach, as presented by the authors, requires 180 days, which hurts the costs of the company as it requires a high investment of time and resources.

According to the previous paragraphs, the current LM approaches used to improve production systems by different authors in different industrial sectors result in medium- and long-term improvements, which is not acceptable today because companies need to find quick results that allow them to remain competitive but, above all, flexible, one of the most important qualities for customers.

The purpose of this research is to present an approach called Lean-Sigma, which aims to address this problem; it is an approach that acts at the speed of Lean “Just do it” providing results in a short period providing an advantage to companies in such a way that the benefits of improvements require less waiting time and therefore, less waste and investment. On the other hand, this approach presents a method to integrate the analysis of the measurement system and the importance of improvement projects.

This study examines the potential of lean sigma’s flexibility for various applications and solutions in production systems. These applications can encompass the design phase and optimize the production process (19). This study investigates the feasibility of utilizing Lean Sigma as a problem-solving approach rather than as a methodology centered around projects. The main objective of this study is to utilize lean-sigma synergy to efficiently complete the entire solution process within a short timeframe (20).

As mentioned, flexibility allows managers to meet customer expectations by coping with changes in demand due to external and internal factors. This was done through a case study in which the methodology was implemented, and the results were validated to demonstrate its effectiveness.

The study was conducted by a company established in the northern region of Mexico from March 6 to May 26, 2022, dedicated to manufacturing metal parts using Press Brake bending machines. The plant currently has 15 bending machines and delivers metallic subassemblies for the final assembly at another facility in the same region.

The metal area has experienced fluctuations in demand owing to increased customer demand, resulting in insufficient parts being delivered to the client to meet the current demand. In the last six months, the on-time delivery rate fluctuated between 85% and 92%, which is below the target of 96% for this process. The primary objective of this study is to improve the on-time delivery (OTD) rate using a lean sigma approach and to prove that the problem can be solved quickly.

The novelty and scientific contribution of the case study reported in this article is that quality problems are solved using the lean-sigma approach, which is based on the principle of solving them at a lean speed. This means that instead of using a traditional continuous improvement approach that takes months or even years to produce results to improve the situation, with the proposed approach, the problem is solved in a few weeks.

The advantage of this approach is that the company stops losing money for long periods owing to quality problems, which contributes to improved flexibility and efficiency in a shorter period. Additionally, the speed with which it provides results, unlike the traditional method that takes from 6 months to 12 months to start the improvement, the proposed method provides results in a matter of weeks.

The remainder of this paper is organized as follows. After a brief introduction, section two describes the methodology used to prove the proposed approach. Section three analyzes the results. Section four reports the conclusions and section five presents some limitations and future research.

II. METHODOLOGY

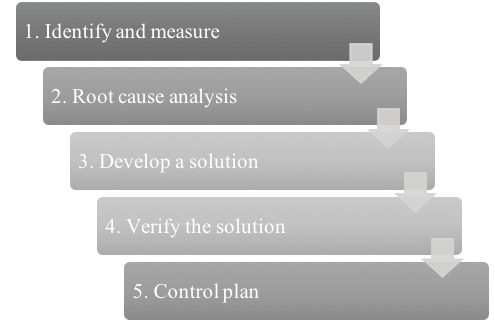

Lean Sigma is an approach focused on problem-solving, as opposed to Lean Six Sigma, which is more project oriented. The methodology is flexible at every stage, allowing for the utilization of engineering, lean, or statistical tools that are now accessible. This study utilized the Lean Sigma technique, which consists of five rapid improvement steps (19), as depicted inFigure 1.

E. Step one. Identify and Measure the Problem

The purpose of the first stage of the proposed methodology is to delimit the problem and explain its size in terms of process capability. To delimit this problem, first, a cross-functional team was formed in the process of interest; in this case, the metal-forming area. The team was composed of personnel from each of the main support teams; in this case, it was composed of Quality Engineer, Manufacturing Engineer, Process Engineer, Maintenance Engineer, Production Supervisor, and Tool Crib Engineer and involved Process Technicians who performed the model changes.

It is essential to mention that it must be sure to include all the support departments to have different points of view and opinions that vary according to the perspective of the person and the department to which they belong, this helps to eliminate the “shop blindness” and to be able to contribute ideas that enrich the solution of the problem. Once the multifunctional team was formed to work on this project, we conducted three sessions with the team performing Gemba Walk, which consists of going through the process of interest in which the project is being carried out.

For this project, one of the process machines is selected, where, based on experience, the setup has the longest time. The first day of the walk consisted of an area tour and analysis of the process metrics, mainly quality, efficiency, and on-time deliveries. The team analyzed the data and generated questions to better understand the situation. To analyze trends, historical data were used for the metric identified as the one with the lowest performance and the one that was off-target; in this case, the on-time delivery (OTD) rate.

The second day of the Gemba walks consisted of a brief brainstorming session involving the previously formed cross-functional team to determine why the production schedule was not currently being met. Approximately 50 ideas were generated, and the team voted and identified the potential cause with the highest score that was used to solve the problem. The third and final days of the Gemba walks were used to define the problems and objectives of the project by documenting them in a Kaizen Charter.

B. Step 2. Root Cause Analysis

Two sessions were held with the team to find a solution to this problem. In the first session, a brainstorming session was generated, in which each team member contributed ideas to the potential cause identified in Step 1. Once the ideas were organized, the Nominal Group Technique tool was used, consisting of each team member evaluating and rating each idea, which was performed anonymously. Each person assigns a weight to five ideas by assigning points from 1 to 5, where 1 indicates that it has the most negligible impact on the problem and 5 indicates that it has a high impact on the problem. The moderator received anonymous weights and captured them on a spreadsheet. Using the weighted ideas, a Pareto diagram is created to prioritize the causes with the highest weighting. Finally, once the idea with the highest weighting was identified, 5 Why’s technique was used to get to the root cause of the problem. In this technique, the entire team participates in the same way, asking themselves five times why the problem occurs. When the fifth reason was reached, the root cause was found, and the problem was solved by eliminating it.

C. Step 3. Develop a Solution

In the third step, based on the root cause identified in the previous step, a lean manufacturing or Six Sigma tool was selected to eliminate the root cause, including the Design of Experiments, Quick Model Changes (SMED), Kanban, and Cellular Manufacturing, among others. In this case, the SMED tool was used to reduce the model change time to less than 10 min. The SMED methodology consists of 4 four stages. In the preliminary stage, the team documents and maps the setup process, noting all the activities and times involved in each of them. In this stage, only the activities were listed with their respective times, and a video of the process was taken to analyze the micro-movements in detail and to see more specific things to be analyzed. In stage one, activities were identified as internal (performed when the equipment was completely stopped) or external (performed when the equipment was operating).

At the end of this stage, the activities were graphed to understand the proportion of internal and external activities. Subsequently, in Stage 2, the team identified those activities currently performed internally that can be transformed into external activities to prepare for all these activities before the machine stops and to have a more efficient model change. The team developed a checklist for the preparation activities and tools required before the setup. Finally, in stage 3, the team developed an action plan to reduce the time of internal activities, some of which were as follows: define a standardized work method and perform activities in parallel and fixtures that allow faster assembly and disassembly of tools, among others.

D. Step 4. Verify the Solution

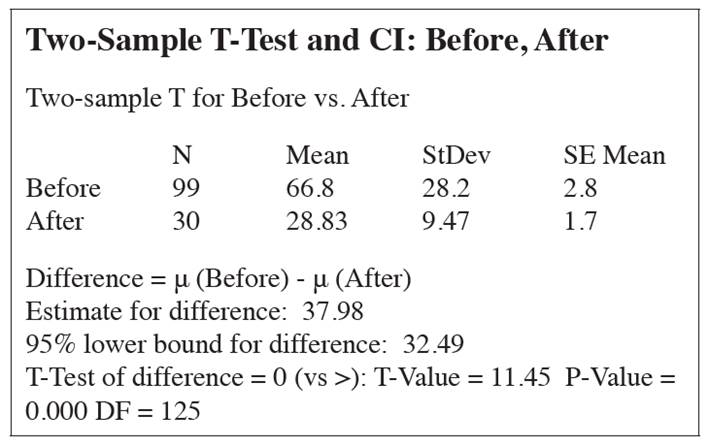

Continuing with Step 4, which consists of verifying the solution, the team performs statistical tests on this part of the methodology to confirm that Step 3 solves the problem. The team collected data from on-time deliveries after implementing the SMED technique. Once the data were obtained, a 2 sample-t statistical test was performed to test the null hypothesis H0: the OTD is the same in its initial form after implementing the proposed methodology and H1: the OTD is lower in its initial form than after implementing the proposed methodology. Once the statistical test was performed, it was concluded that the OTD increased considerably when applying the lean-sigma.

E. Step 5. Control Plan

Finally, in Step 5, a control plan is made, which consists of deploying the work instructions and visual aids to standardize the setup process, as well as a Kaizen event with the first and second shift workers, where they were informed and trained on how to perform model changes, which were mainly asked to properly document the times of model changes to monitor the performance. Finally, an action plan is created to implement and take the lessons learned from other machines and processes.

III. RESULTS AND DISCUSSION

A. Identify and Measure the Problem

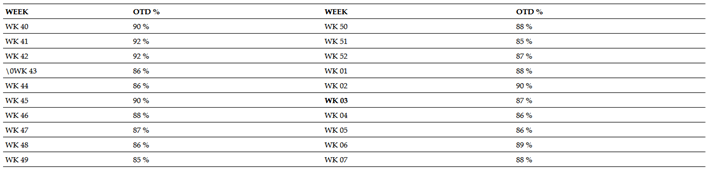

Following the Lean-Sigma approach, the team collects information on the on-time delivery rate, takes data from six months of production control reports to analyze the behavior, and records it inTable 1. A run chart of the collected information is shown inFigure 2.

Based on the data, it can be observed that the on-time delivery rate was between 85 % and 92 % during the last six months. The run graph does not show any trend, but based on the data obtained, it can be observed that 100 % of the time, the quantity of parts required by the customer is not delivered, causing line stoppages.

B. Root Cause Analysis

Once the information has been reviewed and analyzed, essential quality tools are used to determine the root cause of the problem. First, we gathered a multifunctional team from an area composed of a production supervisor, setup technician, quality engineer, manufacturing engineer, and tool crib technician to conduct a brainstorming session.

The session aims to identify the factors that team groups believe affect the on-time delivery indicator and their possible causes. After generating over 50 ideas, reviewing them, and debugging, the potential causes were reduced to three: high setup times, lack of tools, and sudden changes in production plan priorities due to a lack of materials.

Once the three potential causes were identified, the team concluded that the lack of materials could not be controlled and that the lack of tools was caused by not returning them to the tool crib for preventive maintenance; therefore, these causes were discarded.

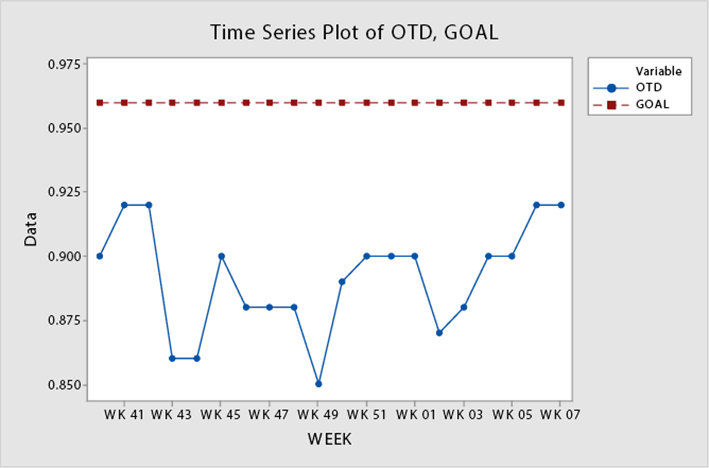

The team decided to focus on high setup times. Subsequently, data on model changes or setup times were collected from the document control area. The data are plotted and shown in Figure 3, where the model changed over time in the last six weeks, ranging from 20 to 115 min, with an average setup time of 68 min.

C. Develop a Solution

The team used the SMED technique to reduce model changes over time. A four-step methodology was used to achieve this, as illustrated in Figure 4.

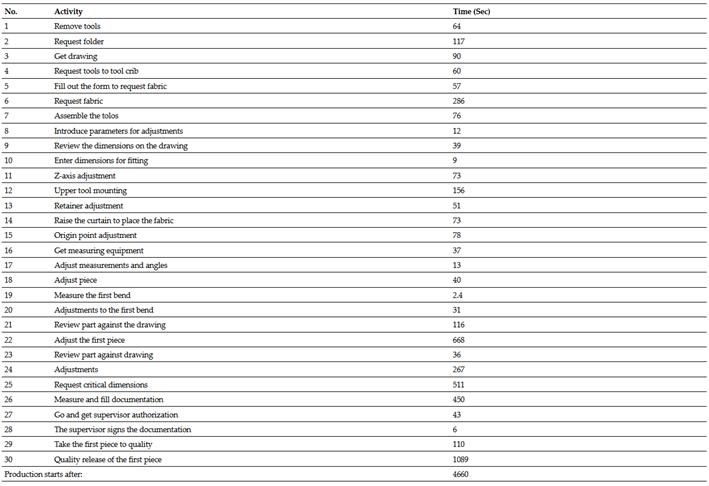

The purpose of the preliminary stage was to identify all the activities that constitute the setup of the process. In this case, recording during the process and listing activities is recommended. To this point, only the activities have been listed, and they were all visualized as the set of activities necessary to perform a model change. Table 2 shows the activities identified during the analysis of model changes. It can be seen that 30 activities comprised the model change, taking 78 minutes.

Many transfers were visualized during the analysis between different departments, such as tool crib, quality, and production.

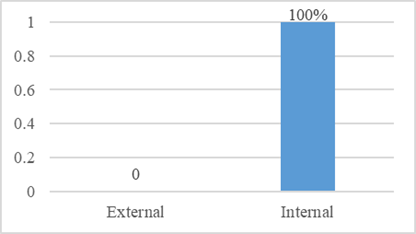

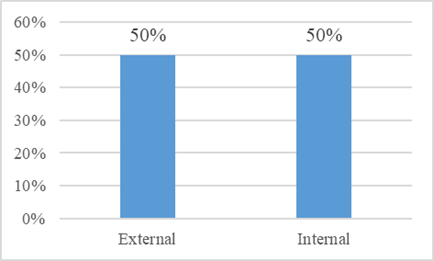

In Stage One, the team identifies and classifies each activity according to how it is currently being executed. The activities were classified into two categories: internal and external. Internal activity was performed while the machine was stopped, whereas external activity was performed while the machine was still running. Figure 5 shows that under the current conditions, 100 % of the 30 activities identified were performed internally.

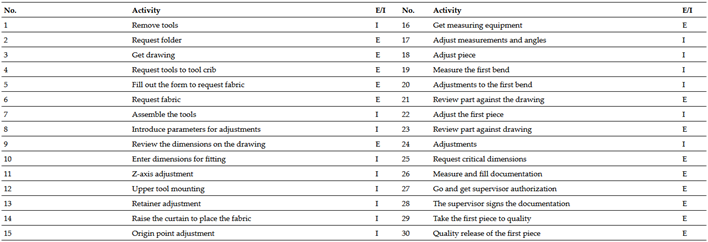

In Stage Two, the team identified activities that, under the current conditions, were performed internally but could be performed externally. This stage aimed to reduce the proportion of internal activities to such a level that the internal activities were close to 1/3 of the total number of activities. From the identified activities, Table 3 determines which of the 30 activities can be converted to internal, which is a fundamental principle of SMED. As shown in Figure 6, 50 %, that is, 15 of the 30 activities, can be converted to internal. This reduces the model changeover time from 78 to 27 minutes, representing a 66 % reduction just by converting the activities to external ones. During this stage, the team developed a checklist with all the necessary materials, documentation, and elements that must be ready before starting the change, thus ensuring that all external activities were ready during the model change.

E: External, I: Internal

In the final stage, the team developed activities to reduce the time required for internal activities. To achieve this, the team created an action plan and followed it up. Some of the activities to be carried out included standardization of the model change time by performing activities in parallel to reduce the time of internal activities. However, standard measurement tools were proposed for purchase so that tools for different model changes could be grouped.

D. Verify the Solution

To test the solution, six weeks of data were taken from the time of model change and on-time deliveries after the implementation of the SMED tool; a control chart was made before vs. after.

There is an increase in the OTD after implementing the Lean-Sigma methodology, with an approximately 8 % increase in the on-time delivery rate and an average of 96.15 % after the implemented improvements.

The model changeover times were compared before and after the implementation of the methodology; approximately 60 % of the model changeover time was reduced in the four weeks following the implementation of SMED.

A Two-Sample test was carried out to probe the hypothesis that the change over time is minor under the initial conditions. As shown inFigure 7, using a p-value of 0, the changeover time was reduced after improvements were applied.

E. Control Plan

As the last step of the methodology, a work instruction was developed to standardize the process of model changes for the bending machines and update the inventories of the maximum and minimum tool cribs. By contrast, a Kaizen event was held to train those involved in the new work method

V. CONCLUSION

The initial information of the process shows an average on-time delivery rate of 89 %, which is outside the company’s minimum goal of 96 %, equivalent to a performance of 0.1 sigma. After applying the Lean Sigma methodology, we can statistically demonstrate an increase in the on-time delivery rate of 8 %; that is, on average, after the proposed improvements, it is 96.5 % above the company’s minimum goal, representing a performance of 2.5 sigmas. Concerning the model changes, a reduction of approximately 60 % was achieved using the SMED approach.

Implementing the lean sigma methodology is carried out in four weeks, fulfilling the requirements of rapid improvement. In summary, using the lean-sigma methodology oriented toward problem-solving instead of focusing on developing improvement projects can achieve the objectives and solve the problem at a low speed.

It can be concluded that using the approach proposed in this study differs from the current approaches in the time it takes to solve a problem; while using Six Sigma can take up to 12 months, using the proposed approach took only 4 to 5 weeks to solve the problem. This helps the company to have more flexibility.

Nowadays, companies cannot afford to continue having losses for not delivering parts on time or for having high scrap rates. This implies that organizations must change the way they are acting to improve processes, they must focus on actually solving the problem quickly. Using current approaches means that the company will continue to lose, become less efficient, less flexible, negatively impacting quality, cost and delivery, variables that are key to be a competitive company in this globalized world we live in today,

IV. LIMITATIONS AND FUTURE RESEARCH

It should be noted that this application is carried out in a metal manufacturing process, and it is possible to use it in any sector. Some of the limitations during implementation are that it requires high commitment from management and the formation of a multidisciplinary team that invests a significant amount of time and effort to solve the problem in a short period. Developing this approach for automotive and medical processes is recommended for future research to demonstrate that the results obtained can be the same or better for other types of processes. It is essential to mention that the projects should be led by a Black Belt knowledgeable in lean manufacturing and Six Sigma tools.